717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

F01D4OA<br />

1. Do not remove this plug<br />

End bearing no. 9 can be easily removed from upper<br />

crankcase half using the following suggested<br />

tool (or equivalent):<br />

– Snap-on hammer puller including:<br />

– handle CJ93-1<br />

– hammer CJ125-6<br />

– claws CJ93-4.<br />

F01J0ZA<br />

Close puller claws so that they can be inserted<br />

in end bearing. Holding claws, turn puller shaft<br />

clockwise so that claws open and become firmly<br />

tight against bearing.<br />

Slide puller hammer outwards and tap puller end.<br />

Retighten claws as necessary to always maintain<br />

them tight against bearing. Continue this way until<br />

bearing completely comes out.<br />

F01D28A<br />

1. End bearing<br />

1<br />

1<br />

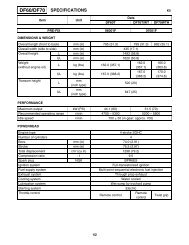

Section 04 ENGINE (2-STROKE)<br />

Subsection 06 (ROTARY VALVE)<br />

CLEANING<br />

Discard all seals and O-rings.<br />

Clean all metal components in a solvent.<br />

Clean oil passages and make sure they are not<br />

clogged.<br />

Clean rotary valve shaft and inside of distance<br />

sleeve no. 14.<br />

INSPECTION<br />

Rotary Valve Cover<br />

Inspect rotary valve cover no. 1 for warpage.<br />

Small deformation can be corrected by surfacing<br />

with fine sand paper on a surface plate. Surface<br />

part against oiled sand paper.<br />

Bearings<br />

Inspect bearings no. 8 and no. 9. Check for scoring,<br />

pitting, chipping or other evidence of wear.<br />

Make sure plastic cage (on bigger bearing) is not<br />

melted. Rotate them and make sure they turn<br />

smoothly.<br />

Gear<br />

Visually check gear wear pattern. It should be<br />

even on tooth length all around. Otherwise it<br />

could indicate a bent shaft, check deflection.<br />

Replace gear if damaged.<br />

Check for presence of brass filings in gear housing.<br />

Rotary Valve Shaft Deflection<br />

Deflection is measured with a dial gauge. Install<br />

rotary valve shaft in crankcase half, without its<br />

gear.<br />

NOTE: End bearing must be in crankcase half.<br />

Measure shaft deflection next to gear splines.<br />

smr2004-Complete Line Up 157