717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section 04 ENGINE (2-STROKE)<br />

Subsection 06 (ROTARY VALVE)<br />

GENERAL<br />

The following verification procedures such as<br />

clearance of rotary valve cover or rotary valve<br />

shaft gear backlash can be performed without<br />

removing engine from watercraft.<br />

However engine must be removed from watercraft<br />

to work on rotary valve shaft/components.<br />

Refer to REMOVAL AND INSTALLATION for engine<br />

removal procedure.<br />

Bottom end must be opened to remove rotary<br />

valve shaft. Refer to BOTTOM END.<br />

INSPECTION ON WATERCRAFT<br />

Remove carburetor(s). Refer to CARBURETOR.<br />

Rotary Valve Cover<br />

Unscrew 4 screws no. 2 and withdraw rotary<br />

valve cover no. 1.<br />

Remove rotary valve no. 13.<br />

Rotary Valve/Cover Clearance<br />

The clearance between the rotary valve and the<br />

cover must be 0.25 – 0.35 mm (.010 –.014 in).<br />

NOTE: If the clearance is lower, this could create<br />

an overheating situation and if the clearance is<br />

higher, this could create a hard starting situation.<br />

There are 2 methods to verify rotary valve/cover<br />

clearance:<br />

– the 45° feeler gauge method<br />

– the soldering wire method.<br />

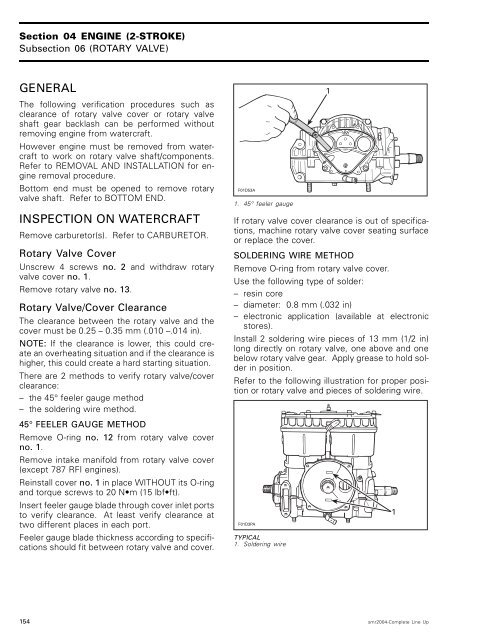

45° FEELER GAUGE METHOD<br />

Remove O-ring no. 12 from rotary valve cover<br />

no. 1.<br />

Remove intake manifold from rotary valve cover<br />

(except 787 RFI engines).<br />

Reinstall cover no. 1 in place WITHOUT its O-ring<br />

andtorquescrewsto20N m(15lbfft). Insert feeler gauge blade through cover inlet ports<br />

to verify clearance. At least verify clearance at<br />

two different places in each port.<br />

Feeler gauge blade thickness according to specifications<br />

should fit between rotary valve and cover.<br />

F01D53A<br />

1. 45° feeler gauge<br />

1<br />

If rotary valve cover clearance is out of specifications,<br />

machine rotary valve cover seating surface<br />

or replace the cover.<br />

SOLDERING WIRE METHOD<br />

Remove O-ring from rotary valve cover.<br />

Use the following type of solder:<br />

– resin core<br />

– diameter: 0.8 mm (.032 in)<br />

– electronic application (available at electronic<br />

stores).<br />

Install 2 soldering wire pieces of 13 mm (1/2 in)<br />

long directly on rotary valve, one above and one<br />

below rotary valve gear. Apply grease to hold solder<br />

in position.<br />

Refer to the following illustration for proper position<br />

or rotary valve and pieces of soldering wire.<br />

F01D3PA<br />

TYPICAL<br />

1. Soldering wire<br />

154 smr2004-Complete Line Up<br />

1