717 Engines

717 Engines

717 Engines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section 04 ENGINE (2-STROKE)<br />

Subsection 05 (BOTTOM END)<br />

F01D1QA<br />

1. Ruler must be aligned with edge of connecting rod here<br />

2. Align ruler here<br />

Crankshaft Deflection<br />

All Models<br />

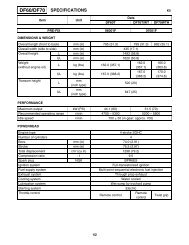

MEASUREMENT MAG SIDE PTO SIDE<br />

Crankshaft<br />

deflection (max.)<br />

2<br />

0.050 mm<br />

(.002 in)<br />

1<br />

0.030 mm<br />

(.001 in)<br />

Crankshaft deflection is measured each end with<br />

a dial indicator.<br />

First, check deflection with crankshaft in<br />

crankcase. If deflection exceeds the specified<br />

tolerance, it can be either ball bearings wear, bent<br />

or twisted crankshaft at connecting rod journal.<br />

F01D1SA<br />

1. Measuring PTO side deflection in crankcase<br />

1<br />

F01D1TA<br />

1<br />

1. Measuring MAG side deflection in crankcase<br />

Remove crankshaft bearings and check deflection<br />

again on V-shaped blocks as illustrated.<br />

F01D97A<br />

1<br />

1. Measuring MAG side deflection on V-shaped blocks<br />

F01D98A<br />

1. Measuring PTO side deflection on V-shaped blocks<br />

142 smr2004-Complete Line Up<br />

1