Tystar Oxidation & Anneal Furnace Operation - Login | Nanolab, UCLA

Tystar Oxidation & Anneal Furnace Operation - Login | Nanolab, UCLA

Tystar Oxidation & Anneal Furnace Operation - Login | Nanolab, UCLA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

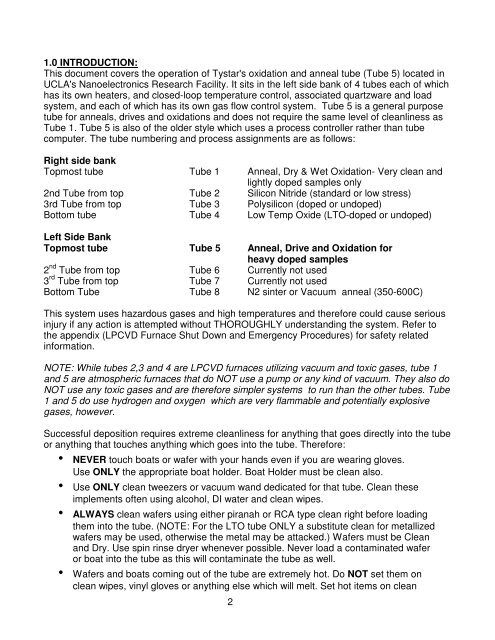

1.0 INTRODUCTION:<br />

This document covers the operation of <strong>Tystar</strong>'s oxidation and anneal tube (Tube 5) located in<br />

<strong>UCLA</strong>'s Nanoelectronics Research Facility. It sits in the left side bank of 4 tubes each of which<br />

has its own heaters, and closed-loop temperature control, associated quartzware and load<br />

system, and each of which has its own gas flow control system. Tube 5 is a general purpose<br />

tube for anneals, drives and oxidations and does not require the same level of cleanliness as<br />

Tube 1. Tube 5 is also of the older style which uses a process controller rather than tube<br />

computer. The tube numbering and process assignments are as follows:<br />

Right side bank<br />

Topmost tube Tube 1 <strong>Anneal</strong>, Dry & Wet <strong>Oxidation</strong>- Very clean and<br />

lightly doped samples only<br />

2nd Tube from top Tube 2 Silicon Nitride (standard or low stress)<br />

3rd Tube from top Tube 3 Polysilicon (doped or undoped)<br />

Bottom tube Tube 4 Low Temp Oxide (LTO-doped or undoped)<br />

Left Side Bank<br />

Topmost tube Tube 5 <strong>Anneal</strong>, Drive and <strong>Oxidation</strong> for<br />

heavy doped samples<br />

2 nd Tube from top Tube 6 Currently not used<br />

3 rd Tube from top Tube 7 Currently not used<br />

Bottom Tube Tube 8 N2 sinter or Vacuum anneal (350-600C)<br />

This system uses hazardous gases and high temperatures and therefore could cause serious<br />

injury if any action is attempted without THOROUGHLY understanding the system. Refer to<br />

the appendix (LPCVD <strong>Furnace</strong> Shut Down and Emergency Procedures) for safety related<br />

information.<br />

NOTE: While tubes 2,3 and 4 are LPCVD furnaces utilizing vacuum and toxic gases, tube 1<br />

and 5 are atmospheric furnaces that do NOT use a pump or any kind of vacuum. They also do<br />

NOT use any toxic gases and are therefore simpler systems to run than the other tubes. Tube<br />

1 and 5 do use hydrogen and oxygen which are very flammable and potentially explosive<br />

gases, however.<br />

Successful deposition requires extreme cleanliness for anything that goes directly into the tube<br />

or anything that touches anything which goes into the tube. Therefore:<br />

• NEVER touch boats or wafer with your hands even if you are wearing gloves.<br />

Use ONLY the appropriate boat holder. Boat Holder must be clean also.<br />

• Use ONLY clean tweezers or vacuum wand dedicated for that tube. Clean these<br />

implements often using alcohol, DI water and clean wipes.<br />

• ALWAYS clean wafers using either piranah or RCA type clean right before loading<br />

them into the tube. (NOTE: For the LTO tube ONLY a substitute clean for metallized<br />

wafers may be used, otherwise the metal may be attacked.) Wafers must be Clean<br />

and Dry. Use spin rinse dryer whenever possible. Never load a contaminated wafer<br />

or boat into the tube as this will contaminate the tube as well.<br />

• Wafers and boats coming out of the tube are extremely hot. Do NOT set them on<br />

clean wipes, vinyl gloves or anything else which will melt. Set hot items on clean<br />

2