Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

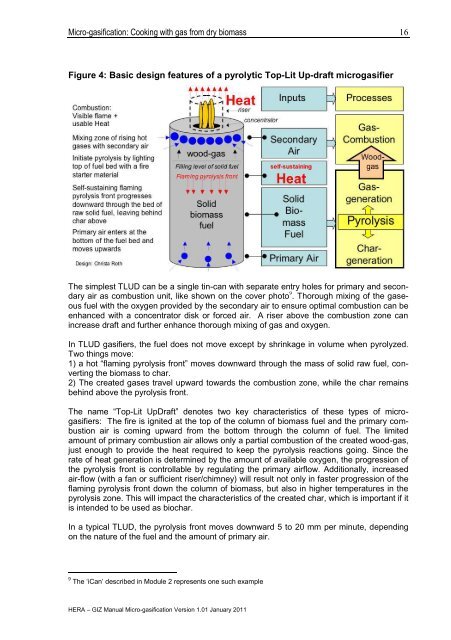

Figure 4: Basic design features of a pyrolytic Top-Lit Up-draft micro<strong>gas</strong>ifier<br />

The simplest TLUD can be a single tin-can <strong>with</strong> separate entry holes for primary and secondary<br />

air as combustion unit, like shown on the cover photo 9 . Thorough mixing of the <strong>gas</strong>eous<br />

fuel <strong>with</strong> the oxygen provided by the secondary air to ensure optimal combustion can be<br />

enhanced <strong>with</strong> a concentrator disk or forced air. A riser above the combustion zone can<br />

increase draft and further enhance thorough mixing of <strong>gas</strong> and oxygen.<br />

In TLUD <strong>gas</strong>ifiers, the fuel does not move except by shrinkage in volume when pyrolyzed.<br />

Two things move:<br />

1) a hot ―flaming pyrolysis front‖ moves downward through the mass of solid raw fuel, converting<br />

the <strong>biomass</strong> to char.<br />

2) The created <strong>gas</strong>es travel upward towards the combustion zone, while the char remains<br />

behind above the pyrolysis front.<br />

The name ―Top-Lit UpDraft‖ denotes two key characteristics of these types of micro<strong>gas</strong>ifiers:<br />

The fire is ignited at the top of the column of <strong>biomass</strong> fuel and the primary combustion<br />

air is coming upward <strong>from</strong> the bottom through the column of fuel. The limited<br />

amount of primary combustion air allows only a partial combustion of the created wood-<strong>gas</strong>,<br />

just enough to provide the heat required to keep the pyrolysis reactions going. Since the<br />

rate of heat generation is determined by the amount of available oxygen, the progression of<br />

the pyrolysis front is controllable by regulating the primary airflow. Additionally, increased<br />

air-flow (<strong>with</strong> a fan or sufficient riser/chimney) will result not only in faster progression of the<br />

flaming pyrolysis front down the column of <strong>biomass</strong>, but also in higher temperatures in the<br />

pyrolysis zone. This will impact the characteristics of the created char, which is important if it<br />

is intended to be used as biochar.<br />

In a typical TLUD, the pyrolysis front moves downward 5 to 20 mm per minute, depending<br />

on the nature of the fuel and the amount of primary air.<br />

9 The ‗iCan‘ described in Module 2 represents one such example<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

16