Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

Annex for Module 3:<br />

ANNEX<br />

Here some rough calculations to demonstrate the magnitude of energy needed to deal <strong>with</strong><br />

moisture in a fuel:<br />

It takes approximately energy in the order of 1 MJ (MegaJoule) to convert 1 kg of dry wood<br />

into char, but much more energy if the wood has high moisture content.<br />

The calculation is based on the following assumptions:<br />

It takes 0.00417 MJ to heat 1 kg of water by 1° Celsius (= 4,186 Joule per g and 1°C)<br />

It takes 0.33 MJ to heat 1 kg of water by 80° <strong>from</strong> 20°C to boiling point at 100°C<br />

It takes 2.25 MJ to evaporate 1 kg of water, meaning to bring it <strong>from</strong> its liquid stage below<br />

boiling point into the vapor stage just above boiling point<br />

It takes 0.63 MJ to heat 1 kg of water vapor <strong>from</strong> 100 °C to 400° C.<br />

Conclusion: Every kg of water contained in a fuel takes up to 3,21 MJ of energy <strong>with</strong> it when<br />

it exits as steam or water vapor.<br />

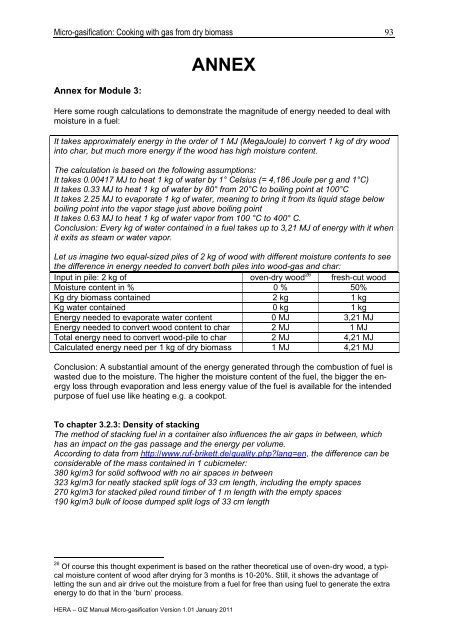

Let us imagine two equal-sized piles of 2 kg of wood <strong>with</strong> different moisture contents to see<br />

the difference in energy needed to convert both piles into wood-<strong>gas</strong> and char:<br />

Input in pile: 2 kg of oven-dry wood 26 fresh-cut wood<br />

Moisture content in % 0 % 50%<br />

Kg dry <strong>biomass</strong> contained 2 kg 1 kg<br />

Kg water contained 0 kg 1 kg<br />

Energy needed to evaporate water content 0 MJ 3,21 MJ<br />

Energy needed to convert wood content to char 2 MJ 1 MJ<br />

Total energy need to convert wood-pile to char 2 MJ 4,21 MJ<br />

Calculated energy need per 1 kg of dry <strong>biomass</strong> 1 MJ 4,21 MJ<br />

Conclusion: A substantial amount of the energy generated through the combustion of fuel is<br />

wasted due to the moisture. The higher the moisture content of the fuel, the bigger the energy<br />

loss through evaporation and less energy value of the fuel is available for the intended<br />

purpose of fuel use like heating e.g. a cookpot.<br />

To chapter 3.2.3: Density of stacking<br />

The method of stacking fuel in a container also influences the air gaps in between, which<br />

has an impact on the <strong>gas</strong> passage and the energy per volume.<br />

According to data <strong>from</strong> http://www.ruf-brikett.de/quality.php?lang=en, the difference can be<br />

considerable of the mass contained in 1 cubicmeter:<br />

380 kg/m3 for solid softwood <strong>with</strong> no air spaces in between<br />

323 kg/m3 for neatly stacked split logs of 33 cm length, including the empty spaces<br />

270 kg/m3 for stacked piled round timber of 1 m length <strong>with</strong> the empty spaces<br />

190 kg/m3 bulk of loose dumped split logs of 33 cm length<br />

26 Of course this thought experiment is based on the rather theoretical use of oven-dry wood, a typical<br />

moisture content of wood after drying for 3 months is 10-20%. Still, it shows the advantage of<br />

letting the sun and air drive out the moisture <strong>from</strong> a fuel for free than using fuel to generate the extra<br />

energy to do that in the ‗burn‘ process.<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

93