Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

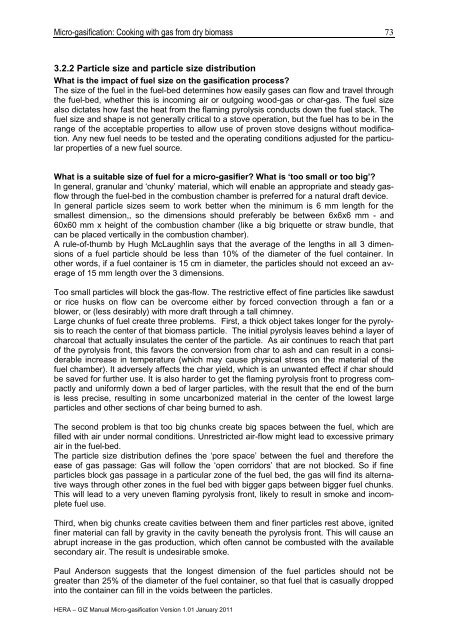

3.2.2 Particle size and particle size distribution<br />

What is the impact of fuel size on the <strong><strong>gas</strong>ification</strong> process?<br />

The size of the fuel in the fuel-bed determines how easily <strong>gas</strong>es can flow and travel through<br />

the fuel-bed, whether this is incoming air or outgoing wood-<strong>gas</strong> or char-<strong>gas</strong>. The fuel size<br />

also dictates how fast the heat <strong>from</strong> the flaming pyrolysis conducts down the fuel stack. The<br />

fuel size and shape is not generally critical to a stove operation, but the fuel has to be in the<br />

range of the acceptable properties to allow use of proven stove designs <strong>with</strong>out modification.<br />

Any new fuel needs to be tested and the operating conditions adjusted for the particular<br />

properties of a new fuel source.<br />

What is a suitable size of fuel for a micro-<strong>gas</strong>ifier? What is „too small or too big‟?<br />

In general, granular and ‗chunky‘ material, which will enable an appropriate and steady <strong>gas</strong>flow<br />

through the fuel-bed in the combustion chamber is preferred for a natural draft device.<br />

In general particle sizes seem to work better when the minimum is 6 mm length for the<br />

smallest dimension,, so the dimensions should preferably be between 6x6x6 mm - and<br />

60x60 mm x height of the combustion chamber (like a big briquette or straw bundle, that<br />

can be placed vertically in the combustion chamber).<br />

A rule-of-thumb by Hugh McLaughlin says that the average of the lengths in all 3 dimensions<br />

of a fuel particle should be less than 10% of the diameter of the fuel container. In<br />

other words, if a fuel container is 15 cm in diameter, the particles should not exceed an average<br />

of 15 mm length over the 3 dimensions.<br />

Too small particles will block the <strong>gas</strong>-flow. The restrictive effect of fine particles like sawdust<br />

or rice husks on flow can be overcome either by forced convection through a fan or a<br />

blower, or (less desirably) <strong>with</strong> more draft through a tall chimney.<br />

Large chunks of fuel create three problems. First, a thick object takes longer for the pyrolysis<br />

to reach the center of that <strong>biomass</strong> particle. The initial pyrolysis leaves behind a layer of<br />

charcoal that actually insulates the center of the particle. As air continues to reach that part<br />

of the pyrolysis front, this favors the conversion <strong>from</strong> char to ash and can result in a considerable<br />

increase in temperature (which may cause physical stress on the material of the<br />

fuel chamber). It adversely affects the char yield, which is an unwanted effect if char should<br />

be saved for further use. It is also harder to get the flaming pyrolysis front to progress compactly<br />

and uniformly down a bed of larger particles, <strong>with</strong> the result that the end of the burn<br />

is less precise, resulting in some uncarbonized material in the center of the lowest large<br />

particles and other sections of char being burned to ash.<br />

The second problem is that too big chunks create big spaces between the fuel, which are<br />

filled <strong>with</strong> air under normal conditions. Unrestricted air-flow might lead to excessive primary<br />

air in the fuel-bed.<br />

The particle size distribution defines the ‗pore space‘ between the fuel and therefore the<br />

ease of <strong>gas</strong> passage: Gas will follow the ‗open corridors‘ that are not blocked. So if fine<br />

particles block <strong>gas</strong> passage in a particular zone of the fuel bed, the <strong>gas</strong> will find its alternative<br />

ways through other zones in the fuel bed <strong>with</strong> bigger gaps between bigger fuel chunks.<br />

This will lead to a very uneven flaming pyrolysis front, likely to result in smoke and incomplete<br />

fuel use.<br />

Third, when big chunks create cavities between them and finer particles rest above, ignited<br />

finer material can fall by gravity in the cavity beneath the pyrolysis front. This will cause an<br />

abrupt increase in the <strong>gas</strong> production, which often cannot be combusted <strong>with</strong> the available<br />

secondary air. The result is undesirable smoke.<br />

Paul Anderson suggests that the longest dimension of the fuel particles should not be<br />

greater than 25% of the diameter of the fuel container, so that fuel that is casually dropped<br />

into the container can fill in the voids between the particles.<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

73