Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

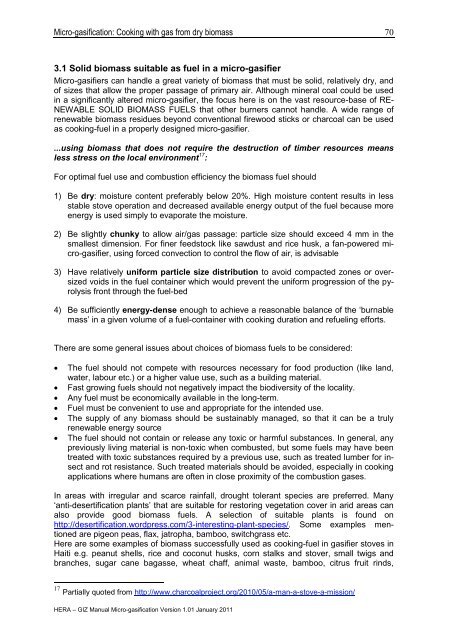

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

3.1 Solid <strong>biomass</strong> suitable as fuel in a micro-<strong>gas</strong>ifier<br />

<strong>Micro</strong>-<strong>gas</strong>ifiers can handle a great variety of <strong>biomass</strong> that must be solid, relatively dry, and<br />

of sizes that allow the proper passage of primary air. Although mineral coal could be used<br />

in a significantly altered micro-<strong>gas</strong>ifier, the focus here is on the vast resource-base of RE-<br />

NEWABLE SOLID BIOMASS FUELS that other burners cannot handle. A wide range of<br />

renewable <strong>biomass</strong> residues beyond conventional firewood sticks or charcoal can be used<br />

as cooking-fuel in a properly designed micro-<strong>gas</strong>ifier.<br />

...using <strong>biomass</strong> that does not require the destruction of timber resources means<br />

less stress on the local environment 17 :<br />

For optimal fuel use and combustion efficiency the <strong>biomass</strong> fuel should<br />

1) Be dry: moisture content preferably below 20%. High moisture content results in less<br />

stable stove operation and decreased available energy output of the fuel because more<br />

energy is used simply to evaporate the moisture.<br />

2) Be slightly chunky to allow air/<strong>gas</strong> passage: particle size should exceed 4 mm in the<br />

smallest dimension. For finer feedstock like sawdust and rice husk, a fan-powered micro-<strong>gas</strong>ifier,<br />

using forced convection to control the flow of air, is advisable<br />

3) Have relatively uniform particle size distribution to avoid compacted zones or oversized<br />

voids in the fuel container which would prevent the uniform progression of the pyrolysis<br />

front through the fuel-bed<br />

4) Be sufficiently energy-dense enough to achieve a reasonable balance of the ‗burnable<br />

mass‘ in a given volume of a fuel-container <strong>with</strong> cooking duration and refueling efforts.<br />

There are some general issues about choices of <strong>biomass</strong> fuels to be considered:<br />

The fuel should not compete <strong>with</strong> resources necessary for food production (like land,<br />

water, labour etc.) or a higher value use, such as a building material.<br />

Fast growing fuels should not negatively impact the biodiversity of the locality.<br />

Any fuel must be economically available in the long-term.<br />

Fuel must be convenient to use and appropriate for the intended use.<br />

The supply of any <strong>biomass</strong> should be sustainably managed, so that it can be a truly<br />

renewable energy source<br />

The fuel should not contain or release any toxic or harmful substances. In general, any<br />

previously living material is non-toxic when combusted, but some fuels may have been<br />

treated <strong>with</strong> toxic substances required by a previous use, such as treated lumber for insect<br />

and rot resistance. Such treated materials should be avoided, especially in cooking<br />

applications where humans are often in close proximity of the combustion <strong>gas</strong>es.<br />

In areas <strong>with</strong> irregular and scarce rainfall, drought tolerant species are preferred. Many<br />

‗anti-desertification plants‘ that are suitable for restoring vegetation cover in arid areas can<br />

also provide good <strong>biomass</strong> fuels. A selection of suitable plants is found on<br />

http://desertification.wordpress.com/3-interesting-plant-species/. Some examples mentioned<br />

are pigeon peas, flax, jatropha, bamboo, switchgrass etc.<br />

Here are some examples of <strong>biomass</strong> successfully used as cooking-fuel in <strong>gas</strong>ifier stoves in<br />

Haiti e.g. peanut shells, rice and coconut husks, corn stalks and stover, small twigs and<br />

branches, sugar cane ba<strong>gas</strong>se, wheat chaff, animal waste, bamboo, citrus fruit rinds,<br />

17 Partially quoted <strong>from</strong> http://www.charcoalproject.org/2010/05/a-man-a-stove-a-mission/<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

70