Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

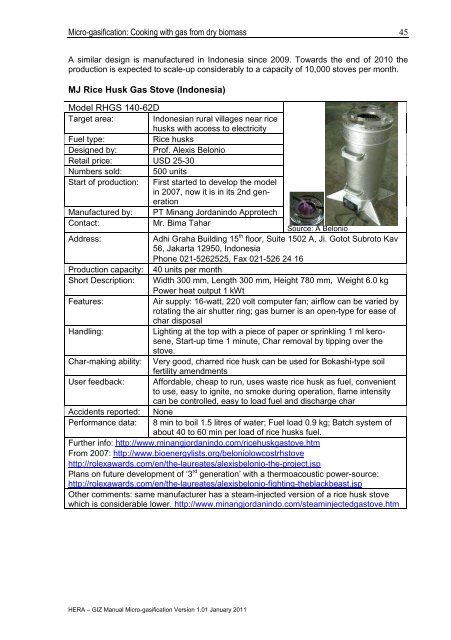

A similar design is manufactured in Indonesia since 2009. Towards the end of 2010 the<br />

production is expected to scale-up considerably to a capacity of 10,000 stoves per month.<br />

MJ Rice Husk Gas Stove (Indonesia)<br />

Model RHGS 140-62D<br />

Target area: Indonesian rural villages near rice<br />

husks <strong>with</strong> access to electricity<br />

Fuel type: Rice husks<br />

Designed by: Prof. Alexis Belonio<br />

Retail price: USD 25-30<br />

Numbers sold: 500 units<br />

Start of production: First started to develop the model<br />

in 2007, now it is in its 2nd generation<br />

Manufactured by: PT Minang Jordanindo Approtech<br />

Contact: Mr. Bima Tahar<br />

Source: A Belonio<br />

Address: Adhi Graha Building 15 th floor, Suite 1502 A, Ji. Gotot Subroto Kav<br />

56, Jakarta 12950, Indonesia<br />

Phone 021-5262525, Fax 021-526 24 16<br />

Production capacity: 40 units per month<br />

Short Description: Width 300 mm, Length 300 mm, Height 780 mm, Weight 6.0 kg<br />

Power heat output 1 kWt<br />

Features: Air supply: 16-watt, 220 volt computer fan; airflow can be varied by<br />

rotating the air shutter ring; <strong>gas</strong> burner is an open-type for ease of<br />

char disposal<br />

Handling: Lighting at the top <strong>with</strong> a piece of paper or sprinkling 1 ml kerosene,<br />

Start-up time 1 minute, Char removal by tipping over the<br />

stove.<br />

Char-making ability: Very good, charred rice husk can be used for Bokashi-type soil<br />

fertility amendments<br />

User feedback: Affordable, cheap to run, uses waste rice husk as fuel, convenient<br />

to use, easy to ignite, no smoke during operation, flame intensity<br />

can be controlled, easy to load fuel and discharge char<br />

Accidents reported: None<br />

Performance data: 8 min to boil 1.5 litres of water; Fuel load 0.9 kg; Batch system of<br />

about 40 to 60 min per load of rice husks fuel.<br />

Further info: http://www.minangjordanindo.com/ricehusk<strong>gas</strong>tove.htm<br />

From 2007: http://www.bioenergylists.org/beloniolowcostrhstove<br />

http://rolexawards.com/en/the-laureates/alexisbelonio-the-project.jsp<br />

Plans on future development of ‗3 rd generation‘ <strong>with</strong> a thermoacoustic power-source:<br />

http://rolexawards.com/en/the-laureates/alexisbelonio-fighting-theblackbeast.jsp<br />

Other comments: same manufacturer has a steam-injected version of a rice husk stove<br />

which is considerable lower. http://www.minangjordanindo.com/steaminjected<strong>gas</strong>tove.htm<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

45