Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

This is a good example how since February 2010 the TLUD-concept was applied in a new<br />

situation following the demand of a specific target group <strong>with</strong> specific needs. In a few<br />

months a working ‗stove‘ and an in-country supply chain was developed <strong>with</strong> a local farmers<br />

association and a group of women. The stove is now retailed at 40 USD.<br />

ESTUFA FINCA in Costa Rica by Art Donnelly (USA)<br />

Starting point: Organic coffee farmers in Costa Rica were looking for a solution to<br />

provide migrant workers <strong>with</strong> clean-burning cook-stoves to improve their health<br />

use farm-residues that need to be burnt for plant pathology reasons for cooking<br />

create biochar for soil amendment to reduce fertilizer use on an organic farm<br />

carbon negative cooking to possibly subsidize <strong>with</strong> carbon credits the placement of<br />

stoves in the make-shift homes of 100,000 seasonal migrant workers.<br />

The result was a TLUD <strong>with</strong> preheated secondary air:<br />

Designed for bigger pots, based on an off-the-shelf 20-liter paint bucket<br />

Converts a multitude of <strong>biomass</strong> <strong>from</strong> a coffee farm to biochar: coffee plant trimmings, to<br />

a certain extent coffee husks, corn cobs, goat droppings, blackberry vines<br />

Primary air through the bottom for easy char-quenching, air control can be added.<br />

Easy to manufacture using patterns, guides and jigs to create pre-cut assembly kits, that<br />

can be assembled <strong>with</strong> simple hand-tools and rivets.<br />

People‘s reaction to the fuel-flexible clean burning stove: ―this is re-inventing the fire.‖<br />

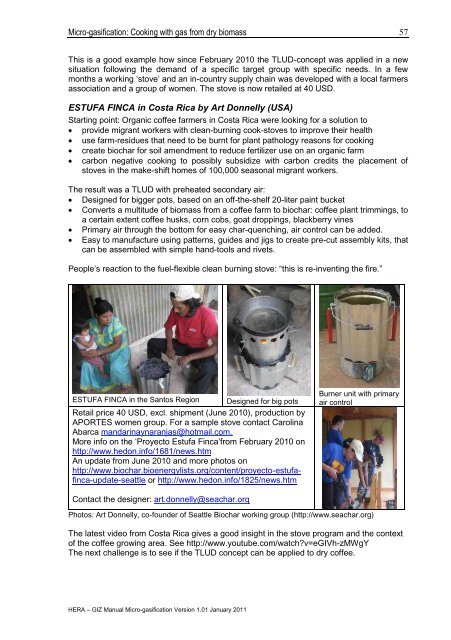

ESTUFA FINCA in the Santos Region Designed for big pots<br />

Retail price 40 USD, excl. shipment (June 2010), production by<br />

APORTES women group. For a sample stove contact Carolina<br />

Abarca mandarinaynaranjas@hotmail.com,<br />

More info on the ‗Proyecto Estufa Finca‘<strong>from</strong> February 2010 on<br />

http://www.hedon.info/1681/news.htm<br />

An update <strong>from</strong> June 2010 and more photos on<br />

http://www.biochar.bioenergylists.org/content/proyecto-estufafinca-update-seattle<br />

or http://www.hedon.info/1825/news.htm<br />

Contact the designer: art.donnelly@seachar.org<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

Burner unit <strong>with</strong> primary<br />

air control<br />

Photos: Art Donnelly, co-founder of Seattle Biochar working group (http://www.seachar.org)<br />

The latest video <strong>from</strong> Costa Rica gives a good insight in the stove program and the context<br />

of the coffee growing area. See http://www.youtube.com/watch?v=eGIVh-zMWgY<br />

The next challenge is to see if the TLUD concept can be applied to dry coffee.<br />

57