Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

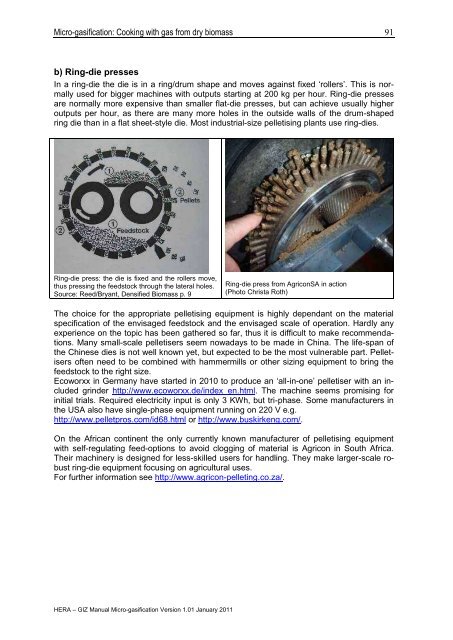

b) Ring-die presses<br />

In a ring-die the die is in a ring/drum shape and moves against fixed ‗rollers‘. This is normally<br />

used for bigger machines <strong>with</strong> outputs starting at 200 kg per hour. Ring-die presses<br />

are normally more expensive than smaller flat-die presses, but can achieve usually higher<br />

outputs per hour, as there are many more holes in the outside walls of the drum-shaped<br />

ring die than in a flat sheet-style die. Most industrial-size pelletising plants use ring-dies.<br />

Ring-die press: the die is fixed and the rollers move,<br />

thus pressing the feedstock through the lateral holes.<br />

Source: Reed/Bryant, Densified Biomass p. 9<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

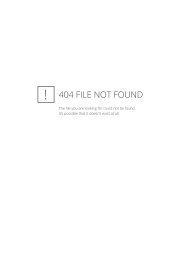

Ring-die press <strong>from</strong> AgriconSA in action<br />

(Photo Christa Roth)<br />

The choice for the appropriate pelletising equipment is highly dependant on the material<br />

specification of the envisaged feedstock and the envisaged scale of operation. Hardly any<br />

experience on the topic has been gathered so far, thus it is difficult to make recommendations.<br />

Many small-scale pelletisers seem nowadays to be made in China. The life-span of<br />

the Chinese dies is not well known yet, but expected to be the most vulnerable part. Pelletisers<br />

often need to be combined <strong>with</strong> hammermills or other sizing equipment to bring the<br />

feedstock to the right size.<br />

Ecoworxx in Germany have started in 2010 to produce an ‗all-in-one‘ pelletiser <strong>with</strong> an included<br />

grinder http://www.ecoworxx.de/index_en.html. The machine seems promising for<br />

initial trials. Required electricity input is only 3 KWh, but tri-phase. Some manufacturers in<br />

the USA also have single-phase equipment running on 220 V e.g.<br />

http://www.pelletpros.com/id68.html or http://www.buskirkeng.com/.<br />

On the African continent the only currently known manufacturer of pelletising equipment<br />

<strong>with</strong> self-regulating feed-options to avoid clogging of material is Agricon in South Africa.<br />

Their machinery is designed for less-skilled users for handling. They make larger-scale robust<br />

ring-die equipment focusing on agricultural uses.<br />

For further information see http://www.agricon-pelleting.co.za/.<br />

91