Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

A new production of rice-husk <strong>gas</strong>ifiers based on the Belonio-design has just started in September<br />

2010 by Mr. Paul Olivier in a Vietnamese-owned workshop in Dalat (Vietnam). All<br />

three <strong>gas</strong>ifiers (reactor diameters of 150, 250 and 500 mm) have the same height (775mm)<br />

and share the basic design. All are manufactured <strong>from</strong> stainless steel and equipped <strong>with</strong> the<br />

same fan, covered by a plate for protection <strong>from</strong> spills.<br />

The speed regulator is mounted on the fan housing. Two heat sink fins on the fan housing<br />

block the transfer of heat to the fan and the fan speed regulator. Power supply can be <strong>from</strong><br />

the grid or for the household-size units via a motorbike battery inexpensively pre-wired for<br />

this purpose. The supplied adapter handles all electrical inputs (Vietnam, Laos, Cambodia,<br />

USA, Colombia and Europe).<br />

The following prices include <strong>gas</strong>ifier (all in stainless steel), fan, speed regulator and adapter.<br />

Prices as per December 2010 do not include a battery or battery charger:<br />

150 <strong>gas</strong>ifier (burn rate 2-4 kg <strong>biomass</strong>/h) = 52 USD<br />

250 <strong>gas</strong>ifier (burn rate 5-10 kg <strong>biomass</strong>/h) = 92 USD<br />

500 <strong>gas</strong>ifier (burn rate 20-40 kg <strong>biomass</strong>/h) = 232 USD (for institutions, greenhouses)<br />

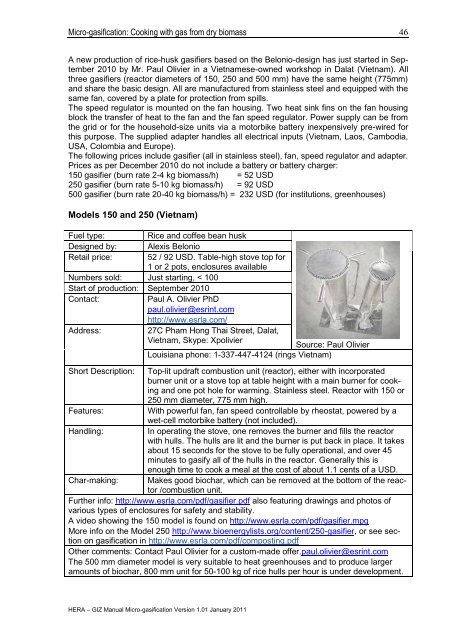

Models 150 and 250 (Vietnam)<br />

Fuel type: Rice and coffee bean husk<br />

Designed by: Alexis Belonio<br />

Retail price: 52 / 92 USD. Table-high stove top for<br />

1 or 2 pots, enclosures available<br />

Numbers sold: Just starting, < 100<br />

Start of production: September 2010<br />

Contact: Paul A. Olivier PhD<br />

paul.olivier@esrint.com<br />

http://www.esrla.com/<br />

Address: 27C Pham Hong Thai Street, Dalat,<br />

Vietnam, Skype: Xpolivier<br />

Source: Paul Olivier<br />

Louisiana phone: 1-337-447-4124 (rings Vietnam)<br />

Short Description: Top-lit updraft combustion unit (reactor), either <strong>with</strong> incorporated<br />

burner unit or a stove top at table height <strong>with</strong> a main burner for cooking<br />

and one pot hole for warming. Stainless steel. Reactor <strong>with</strong> 150 or<br />

250 mm diameter, 775 mm high.<br />

Features: With powerful fan, fan speed controllable by rheostat, powered by a<br />

wet-cell motorbike battery (not included).<br />

Handling: In operating the stove, one removes the burner and fills the reactor<br />

<strong>with</strong> hulls. The hulls are lit and the burner is put back in place. It takes<br />

about 15 seconds for the stove to be fully operational, and over 45<br />

minutes to <strong>gas</strong>ify all of the hulls in the reactor. Generally this is<br />

enough time to cook a meal at the cost of about 1.1 cents of a USD.<br />

Char-making: Makes good biochar, which can be removed at the bottom of the reactor<br />

/combustion unit.<br />

Further info: http://www.esrla.com/pdf/<strong>gas</strong>ifier.pdf also featuring drawings and photos of<br />

various types of enclosures for safety and stability.<br />

A video showing the 150 model is found on http://www.esrla.com/pdf/<strong>gas</strong>ifier.mpg<br />

More info on the Model 250 http://www.bioenergylists.org/content/250-<strong>gas</strong>ifier, or see section<br />

on <strong><strong>gas</strong>ification</strong> in http://www.esrla.com/pdf/composting.pdf<br />

Other comments: Contact Paul Olivier for a custom-made offer.paul.olivier@esrint.com<br />

The 500 mm diameter model is very suitable to heat greenhouses and to produce larger<br />

amounts of biochar, 800 mm unit for 50-100 kg of rice hulls per hour is under development.<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

46