Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Micro-gasification: Cooking with gas from biomass - Amper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

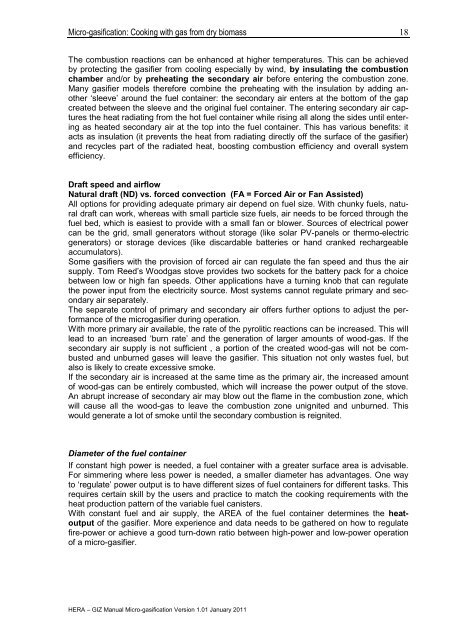

<strong>Micro</strong>-<strong><strong>gas</strong>ification</strong>: <strong>Cooking</strong> <strong>with</strong> <strong>gas</strong> <strong>from</strong> dry <strong>biomass</strong><br />

The combustion reactions can be enhanced at higher temperatures. This can be achieved<br />

by protecting the <strong>gas</strong>ifier <strong>from</strong> cooling especially by wind, by insulating the combustion<br />

chamber and/or by preheating the secondary air before entering the combustion zone.<br />

Many <strong>gas</strong>ifier models therefore combine the preheating <strong>with</strong> the insulation by adding another<br />

‗sleeve‘ around the fuel container: the secondary air enters at the bottom of the gap<br />

created between the sleeve and the original fuel container. The entering secondary air captures<br />

the heat radiating <strong>from</strong> the hot fuel container while rising all along the sides until entering<br />

as heated secondary air at the top into the fuel container. This has various benefits: it<br />

acts as insulation (it prevents the heat <strong>from</strong> radiating directly off the surface of the <strong>gas</strong>ifier)<br />

and recycles part of the radiated heat, boosting combustion efficiency and overall system<br />

efficiency.<br />

Draft speed and airflow<br />

Natural draft (ND) vs. forced convection (FA = Forced Air or Fan Assisted)<br />

All options for providing adequate primary air depend on fuel size. With chunky fuels, natural<br />

draft can work, whereas <strong>with</strong> small particle size fuels, air needs to be forced through the<br />

fuel bed, which is easiest to provide <strong>with</strong> a small fan or blower. Sources of electrical power<br />

can be the grid, small generators <strong>with</strong>out storage (like solar PV-panels or thermo-electric<br />

generators) or storage devices (like discardable batteries or hand cranked rechargeable<br />

accumulators).<br />

Some <strong>gas</strong>ifiers <strong>with</strong> the provision of forced air can regulate the fan speed and thus the air<br />

supply. Tom Reed‘s Wood<strong>gas</strong> stove provides two sockets for the battery pack for a choice<br />

between low or high fan speeds. Other applications have a turning knob that can regulate<br />

the power input <strong>from</strong> the electricity source. Most systems cannot regulate primary and secondary<br />

air separately.<br />

The separate control of primary and secondary air offers further options to adjust the performance<br />

of the micro<strong>gas</strong>ifier during operation.<br />

With more primary air available, the rate of the pyrolitic reactions can be increased. This will<br />

lead to an increased ‗burn rate‘ and the generation of larger amounts of wood-<strong>gas</strong>. If the<br />

secondary air supply is not sufficient , a portion of the created wood-<strong>gas</strong> will not be combusted<br />

and unburned <strong>gas</strong>es will leave the <strong>gas</strong>ifier. This situation not only wastes fuel, but<br />

also is likely to create excessive smoke.<br />

If the secondary air is increased at the same time as the primary air, the increased amount<br />

of wood-<strong>gas</strong> can be entirely combusted, which will increase the power output of the stove.<br />

An abrupt increase of secondary air may blow out the flame in the combustion zone, which<br />

will cause all the wood-<strong>gas</strong> to leave the combustion zone unignited and unburned. This<br />

would generate a lot of smoke until the secondary combustion is reignited.<br />

Diameter of the fuel container<br />

If constant high power is needed, a fuel container <strong>with</strong> a greater surface area is advisable.<br />

For simmering where less power is needed, a smaller diameter has advantages. One way<br />

to ‗regulate‘ power output is to have different sizes of fuel containers for different tasks. This<br />

requires certain skill by the users and practice to match the cooking requirements <strong>with</strong> the<br />

heat production pattern of the variable fuel canisters.<br />

With constant fuel and air supply, the AREA of the fuel container determines the heatoutput<br />

of the <strong>gas</strong>ifier. More experience and data needs to be gathered on how to regulate<br />

fire-power or achieve a good turn-down ratio between high-power and low-power operation<br />

of a micro-<strong>gas</strong>ifier.<br />

HERA – GIZ Manual <strong>Micro</strong>-<strong><strong>gas</strong>ification</strong> Version 1.01 January 2011<br />

18