DUAL ®& DUAL ® SH SINGLE ®& SINGLE ® SH - Expert-CM

DUAL ®& DUAL ® SH SINGLE ®& SINGLE ® SH - Expert-CM

DUAL ®& DUAL ® SH SINGLE ®& SINGLE ® SH - Expert-CM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

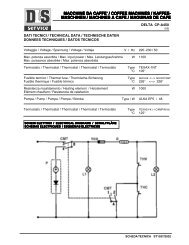

SERVICE (cont.)<br />

OVERFLOW PROTECTION SWITCH<br />

TL5<br />

TL4<br />

TL3<br />

TL2<br />

TL1<br />

SET<br />

LOCK<br />

SET LOCK<br />

J2<br />

J1<br />

TL5<br />

TL4<br />

TL3<br />

TL2<br />

TL1<br />

SET<br />

LOCK<br />

SET LOCK<br />

.500 gpm FLOW<br />

BUNN<br />

90 psig max operating pressure<br />

Strainer/Flow Control # 22300.0750<br />

(Repl. Flow Washer #20526.0750)<br />

(Repl. Screen #23721.0000)<br />

J2<br />

J1<br />

READY SELECTOR<br />

ON / WARMER START<br />

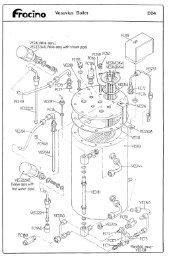

FIG. 24 OVERFLOW PROTEC-<br />

TION SWITCH<br />

START ON / WARMER SELECTOR READY<br />

Location:<br />

The overflow protection switch is located inside the<br />

hood on the tank inside the copper overflow cup.<br />

To test the overflow protection switch, access will<br />

also be needed to the level control board or electronic<br />

control assembly and terminal block.<br />

Test Procedure:<br />

1. Disconnect the brewer from the power source.<br />

2. Remove the wire nuts connecting the red wires<br />

from the overflow protection switch to the black<br />

wire from the terminal block and blue wire from<br />

the thermostat or the black and red wires from the<br />

electronic control assembly.<br />

3. Check for continuity across the overflow protection<br />

switch red wires only until the plastic float is<br />

raised and check that continuity returns when the<br />

plastic float is again lowered.<br />

If continuity is present as described, reconnect the<br />

red wires to the blue wire from the thermostat and<br />

Liquid Level Control and the black wire from terminal<br />

block or black and red wires from electronic control<br />

assembly.<br />

If continuity is not present as described, replace the<br />

1⁄2 gal<br />

1 1⁄2 gal<br />

1 gal<br />

1⁄2 gal<br />

1 1⁄2 gal<br />

1 gal<br />

P2194<br />

Page 25<br />

overflow protection switch.<br />

Removal and Replacement:<br />

1. Disconnect the red leads from the overflow protection<br />

switch from the blue wire from the thermostat<br />

and the black wire from the terminal block or black<br />

and red wires from electronic control assembly.<br />

2. Remove the nut beneath the copper overflow<br />

cup.<br />

3. Remove the entire switch assembly from the<br />

cup.<br />

4. Place the new switch assembly into the cup, wires<br />

first. Make sure that the gasket is in place around<br />

the threaded switch stem.<br />

NOTE - The magnets must be at the top of float and<br />

there must be NO adjusting washers installed for the<br />

overflow protection switch to operate properly.<br />

5. Install the nut beneath the copper overflow cup.<br />

Be sure not to overtighten.<br />

6. Refer to Fig. 25 when reconnecting wires.<br />

RED to BLK Wire<br />

form Terminal Block<br />

or<br />

RED to BLK Lead<br />

from J3-12<br />

RED to BLU Lead<br />

from Thermostat &<br />

Liquid Level Control<br />

or<br />

RED to RED Lead<br />

from J3-11<br />

FIG. 25 OVERFLOW PROTECTION<br />

SWITCH TERMINALS<br />

P795<br />

41976 031709