English - StellarSupport - John Deere

English - StellarSupport - John Deere

English - StellarSupport - John Deere

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

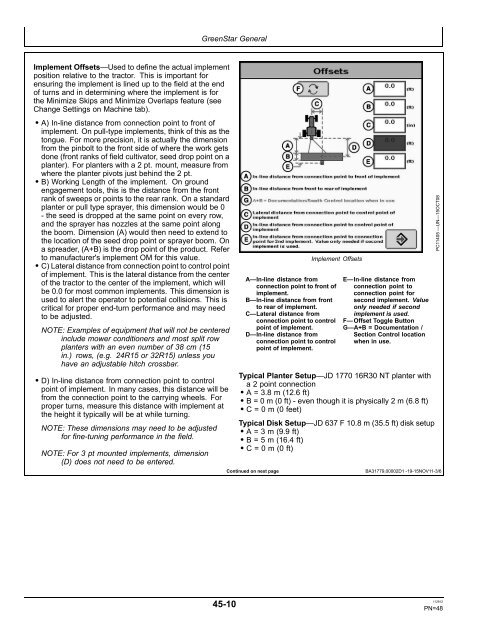

Implement Offsets—Used to define the actual implement<br />

position relative to the tractor. This is important for<br />

ensuring the implement is lined up to the field at the end<br />

of turns and in determining where the implement is for<br />

the Minimize Skips and Minimize Overlaps feature (see<br />

Change Settings on Machine tab).<br />

• A) In-line distance from connection point to front of<br />

implement. On pull-type implements, think of this as the<br />

tongue. For more precision, it is actually the dimension<br />

from the pinbolt to the front side of where the work gets<br />

done (front ranks of field cultivator, seed drop point on a<br />

planter). For planters with a 2 pt. mount, measure from<br />

where the planter pivots just behind the 2 pt.<br />

• B) Working Length of the implement. On ground<br />

engagement tools, this is the distance from the front<br />

rank of sweeps or points to the rear rank. On a standard<br />

planter or pull type sprayer, this dimension would be 0<br />

- the seed is dropped at the same point on every row,<br />

and the sprayer has nozzles at the same point along<br />

the boom. Dimension (A) would then need to extend to<br />

the location of the seed drop point or sprayer boom. On<br />

a spreader, (A+B) is the drop point of the product. Refer<br />

to manufacturer's implement OM for this value.<br />

• C) Lateral distance from connection point to control point<br />

of implement. This is the lateral distance from the center<br />

of the tractor to the center of the implement, which will<br />

be 0.0 for most common implements. This dimension is<br />

used to alert the operator to potential collisions. This is<br />

critical for proper end-turn performance and may need<br />

to be adjusted.<br />

NOTE: Examples of equipment that will not be centered<br />

include mower conditioners and most split row<br />

planters with an even number of 38 cm (15<br />

in.) rows, (e.g. 24R15 or 32R15) unless you<br />

have an adjustable hitch crossbar.<br />

• D) In-line distance from connection point to control<br />

point of implement. In many cases, this distance will be<br />

from the connection point to the carrying wheels. For<br />

proper turns, measure this distance with implement at<br />

the height it typically will be at while turning.<br />

NOTE: These dimensions may need to be adjusted<br />

for fine-tuning performance in the field.<br />

NOTE: For 3 pt mounted implements, dimension<br />

(D) does not need to be entered.<br />

GreenStar General<br />

45-10<br />

Implement Offsets<br />

A—In-line distance from<br />

connection point to front of<br />

implement.<br />

B—In-line distance from front<br />

to rear of implement.<br />

C—Lateral distance from<br />

connection point to control<br />

point of implement.<br />

D—In-line distance from<br />

connection point to control<br />

point of implement.<br />

E—In-line distance from<br />

connection point to<br />

connection point for<br />

second implement. Value<br />

only needed if second<br />

implement is used.<br />

F— Offset Toggle Button<br />

G—A+B = Documentation /<br />

Section Control location<br />

when in use.<br />

Typical Planter Setup—JD 1770 16R30 NT planter with<br />

a 2 point connection<br />

• A = 3.8 m (12.6 ft)<br />

• B = 0 m (0 ft) - even though it is physically 2 m (6.8 ft)<br />

• C = 0 m (0 feet)<br />

Typical Disk Setup—JD 637 F 10.8 m (35.5 ft) disk setup<br />

• A = 3 m (9.9 ft)<br />

• B = 5 m (16.4 ft)<br />

• C = 0 m (0 ft)<br />

Continued on next page BA31779,00002D1 -19-15NOV11-3/6<br />

PC11405 —UN—15OCT08<br />

112912<br />

PN=48