- Page 1 and 2: Thermophysics 2009 29 th and 30 th

- Page 3 and 4: Content Ivan Baník, Jozefa Lukovi

- Page 5 and 6: Measurement of the thermo‐physica

- Page 7 and 8: As the right side of the previous r

- Page 9 and 10: The initial vector k r in the k1, k

- Page 11 and 12: 2.4 The computer programs testing T

- Page 13 and 14: Investigation of moisture influence

- Page 15: ⎛ t t ⎞ −1 ⋅ ln⎜ ⎝ tm t

- Page 19 and 20: for a new building have to be great

- Page 21 and 22: Fig.1. Photo of the hot ball sensor

- Page 23 and 24: Fig.6.Left: formation of blocks. Ri

- Page 25 and 26: 4. Conclusions With this experiment

- Page 27 and 28: 1a. Three‐dimensional temperature

- Page 29 and 30: n+ ∞ ( ) 4 ( ) ∑ π n= 1 ( 2 1)

- Page 31 and 32: a 2 2 ( Fo) ⎛ l ⎞ r = ⎜ ⎟

- Page 33 and 34: Substitution of ordinates of the in

- Page 35 and 36: Moisture transport through porous m

- Page 37 and 38: Data acquired through the hot ball

- Page 39 and 40: In this way, the water spreading wa

- Page 41 and 42: Thermal conductivity [W m -1 K -1 ]

- Page 43 and 44: Relationship between relative permi

- Page 45 and 46: ( ) i n Φ − Φ K i = ki i i, cri

- Page 47 and 48: Figure 4: Comparison of measured an

- Page 49 and 50: Computational modelling of coupled

- Page 51 and 52: a ξ = d 2 ( lnκ − lnκ ) lnξ +

- Page 53 and 54: on the results of experiments and c

- Page 55 and 56: Figures 8a, b: Moisture content (a)

- Page 57 and 58: Conclusions The computer simulation

- Page 59 and 60: properties as are the bulk density,

- Page 61 and 62: elation determined from the measure

- Page 63 and 64: In the evaluation of the difference

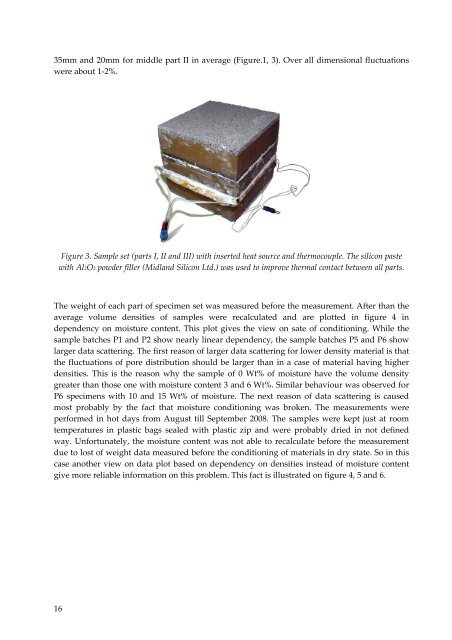

- Page 65 and 66: Heat source I RT-Lab II Specimen Ch

- Page 67 and 68:

Thermal conductivity [W m -1 K -1 ]

- Page 69 and 70:

silicon glue epoxy probe hole Figur

- Page 71 and 72:

Computational modelling of temperat

- Page 73 and 74:

1 2 3 EXT. INT. 5-15 50-60 375 5 Nu

- Page 75 and 76:

Fig. 4 shows a comparison of the re

- Page 77 and 78:

Envelope D Figs. 14, 15 present the

- Page 79 and 80:

Application of computational modell

- Page 81 and 82:

Table 2: Basic material characteris

- Page 83 and 84:

Temperature [K] 320 300 280 260 240

- Page 85 and 86:

Mineral wool has the same effect as

- Page 87 and 88:

Nowadays, most of concrete building

- Page 89 and 90:

Figure 2: Ceramic dessicator plate

- Page 91 and 92:

dessicators are decreased by the pe

- Page 93 and 94:

The surface water vapour diffusion

- Page 95 and 96:

where h is the Planck constant and

- Page 97 and 98:

(a) (b) Figure 2: Schematic picture

- Page 99 and 100:

[7] BLUM, V.; HART, G. L. W.; WALOR

- Page 101 and 102:

Analysis of moisture hysteresis of

- Page 103 and 104:

The water content during scanning b

- Page 105 and 106:

All analysed cellulose based materi

- Page 107 and 108:

Thermodilatometry of ceramics using

- Page 109 and 110:

of the dilatometric cell with the s

- Page 111 and 112:

thermal expansion / % 2 1,5 1 0,5 0

- Page 113 and 114:

[8] KAMSEU, E. ; LEONELLI, C. ; BOC

- Page 115 and 116:

heating, the temperatures were meas

- Page 117 and 118:

temperature difference [°C] 140 12

- Page 119 and 120:

temperature difference [°C] 180 16

- Page 121 and 122:

[4] ČÍČEL, B. - NOVÁK, I. - HOR

- Page 123 and 124:

space and the crystallization press

- Page 125 and 126:

20 mm face to the penetrating KNO3

- Page 127 and 128:

Cb [kg/m 3 (sample)] 1800 1600 1400

- Page 129 and 130:

D [m 2 /s] 1.0E-03 1.0E-04 1.0E-05

- Page 131 and 132:

Thermomechanical modelling of matur

- Page 133 and 134:

ε ε (velocity rates) a x , t . By

- Page 135 and 136:

ε ε w v The process of redistribu

- Page 137 and 138:

Conclusion In this paper we have br

- Page 139 and 140:

most popular among direct technique

- Page 141 and 142:

• Closed pores (not available for

- Page 143 and 144:

espective volume of inclusions frac

- Page 145 and 146:

Summary Among the indirect methods

- Page 147 and 148:

Thermal, hygric and salt‐related

- Page 149 and 150:

The water vapor diffusion coefficie

- Page 151 and 152:

Thermal properties Thermal conducti

- Page 153 and 154:

On the other hand, apparent moistur

- Page 155 and 156:

Thermal conductivity.. [Wm -1 K -1

- Page 157 and 158:

Properties of innovative materials

- Page 159 and 160:

or hygrothermal analysis of buildin

- Page 161 and 162:

where Da is the diffusion coefficie

- Page 163 and 164:

The bending and compressive strengt

- Page 165 and 166:

moisture diffusivity which was caus

- Page 167 and 168:

Abstract: Thermal conductivity in d

- Page 169 and 170:

, (5) where λ is thermal conductiv

- Page 171 and 172:

4.Measured values and calculation I

- Page 173 and 174:

Acknowledgements This research has

- Page 175 and 176:

3 Results During heating, the struc

- Page 177 and 178:

Acknowledgment This work was suppor

- Page 179 and 180:

mixture by short mixing, the mixtur

- Page 181 and 182:

detected by MIP and thus the intrus

- Page 183 and 184:

diffusion. The general Arrhenius eq

- Page 185 and 186:

Thermal conductivity measurement of

- Page 187 and 188:

S s o 2 4 4 λ ∇ T = wεσ ( T

- Page 189 and 190:

steel (20 W m ‐1 K ‐1 ) is arou

- Page 191 and 192:

significant larger cross‐section.

- Page 193 and 194:

Water and heat transport properties

- Page 195 and 196:

The open porosity ψ0 [%], bulk den

- Page 197 and 198:

Table 3: Basic material parameters

- Page 199 and 200:

Acknowledgements This research has

- Page 201 and 202:

comparison of results we can determ

- Page 203 and 204:

specimen and heat source R at infin

- Page 205 and 206:

6.E-04 4.E-04 ΔU (V) 2.E-04 0.E+00

- Page 207 and 208:

[3] KUBIČÁR Ľ. Pulse method of m

- Page 209 and 210:

silicate binders as partial replace

- Page 211 and 212:

Table 2. Mechanical properties HPC

- Page 213 and 214:

HPC Table 5. Water transport proper

- Page 215 and 216:

The results obtained for using high

- Page 217 and 218:

aerospace engineering, cryogenic en

- Page 219 and 220:

4 ⎡ ′ ⎤ Δθ( t) = ⎢ l ∫

- Page 221 and 222:

Alloy Components Weight Percent, [%

- Page 223 and 224:

Figure 8: Final results of the ther

- Page 225 and 226:

Figure 11: Preliminary results of t

- Page 227 and 228:

In case of the FeNi35, FeNi39 and F

- Page 229 and 230:

Experimental Methods Compressive st

- Page 231 and 232:

Type of mixture Water transport pro

- Page 233 and 234:

Thermal properties The thermal para

- Page 235 and 236:

Identification of Some Thermophysic

- Page 237 and 238:

Physical model of the direct proble

- Page 239 and 240:

2 ( λ − Bi) sin( λ) − 2λ Bic

- Page 241 and 242:

To calculate the sensitivity coeffi

- Page 243 and 244:

symmetry of the specimen when the t

- Page 245 and 246:

Figure 5: View of experimental setu

- Page 247 and 248:

During the inverse calculations the

- Page 249 and 250:

temperature dependence for the blac

- Page 251 and 252:

4. Conclusions The results of the t

- Page 253 and 254:

cross‐planar direction applying s

- Page 255 and 256:

3. Thermal diffusivity identificati

- Page 257 and 258:

Table 2: Effect of the convective h

- Page 259 and 260:

[2] BODZENTA, J.; BURAKA, B.; NOWAK

- Page 261 and 262:

doc. Ing. Jiří Vala, CSc. Brno Un

- Page 263 and 264:

263