Conference, Proceedings

Conference, Proceedings

Conference, Proceedings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

mixture by short mixing, the mixture put into the forms, evacuated for one hour and<br />

autoclaved.<br />

Before the measurements, all specimens were dried in an oven at 110°C. In the experiments,<br />

four various sample pre‐treatment conditions were tested: reference specimen not exposed to<br />

any load (denoted as T‐ref in what follows), specimen exposed to a gradual temperature<br />

increase up to 600, 800 and 1000°C during two hours, then left for another 2 hours at the final<br />

temperature and slowly cooled (denoted as T‐600, T‐800 and T‐1000 according to the loading<br />

temperature).<br />

Experimental Methods<br />

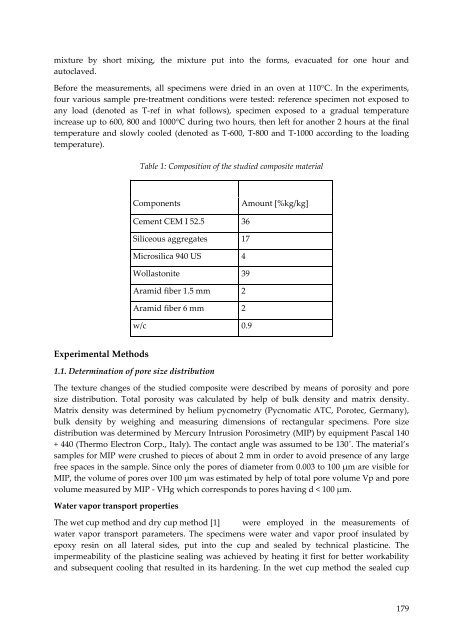

Table 1: Composition of the studied composite material<br />

Components Amount [%kg/kg]<br />

Cement CEM I 52.5 36<br />

Siliceous aggregates 17<br />

Microsilica 940 US 4<br />

Wollastonite 39<br />

Aramid fiber 1.5 mm 2<br />

Aramid fiber 6 mm 2<br />

w/c 0.9<br />

1.1. Determination of pore size distribution<br />

The texture changes of the studied composite were described by means of porosity and pore<br />

size distribution. Total porosity was calculated by help of bulk density and matrix density.<br />

Matrix density was determined by helium pycnometry (Pycnomatic ATC, Porotec, Germany),<br />

bulk density by weighing and measuring dimensions of rectangular specimens. Pore size<br />

distribution was determined by Mercury Intrusion Porosimetry (MIP) by equipment Pascal 140<br />

+ 440 (Thermo Electron Corp., Italy). The contact angle was assumed to be 130˚. The material’s<br />

samples for MIP were crushed to pieces of about 2 mm in order to avoid presence of any large<br />

free spaces in the sample. Since only the pores of diameter from 0.003 to 100 μm are visible for<br />

MIP, the volume of pores over 100 μm was estimated by help of total pore volume Vp and pore<br />

volume measured by MIP ‐ VHg which corresponds to pores having d < 100 μm.<br />

Water vapor transport properties<br />

The wet cup method and dry cup method [1] were employed in the measurements of<br />

water vapor transport parameters. The specimens were water and vapor proof insulated by<br />

epoxy resin on all lateral sides, put into the cup and sealed by technical plasticine. The<br />

impermeability of the plasticine sealing was achieved by heating it first for better workability<br />

and subsequent cooling that resulted in its hardening. In the wet cup method the sealed cup<br />

179