Conference, Proceedings

Conference, Proceedings

Conference, Proceedings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

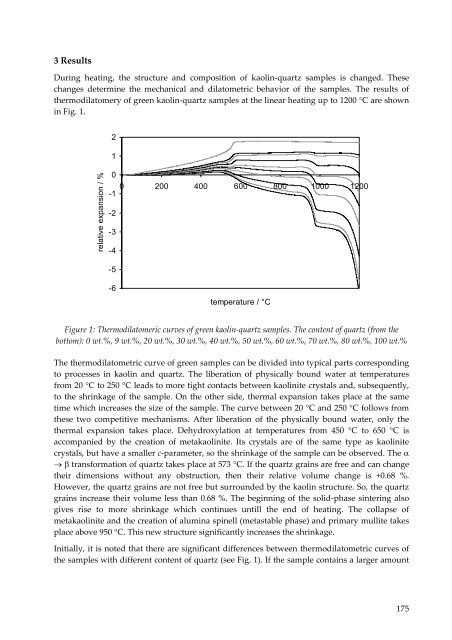

3 Results<br />

During heating, the structure and composition of kaolin‐quartz samples is changed. These<br />

changes determine the mechanical and dilatometric behavior of the samples. The results of<br />

thermodilatomery of green kaolin‐quartz samples at the linear heating up to 1200 °C are shown<br />

in Fig. 1.<br />

relative expansion / %<br />

2<br />

1<br />

0<br />

-1<br />

-2<br />

-3<br />

-4<br />

-5<br />

-6<br />

0 200 400 600 800 1000 1200<br />

temperature / °C<br />

Figure 1: Thermodilatomeric curves of green kaolin‐quartz samples. The content of quartz (from the<br />

bottom): 0 wt.%, 9 wt.%, 20 wt.%, 30 wt.%, 40 wt.%, 50 wt.%, 60 wt.%, 70 wt.%, 80 wt.%, 100 wt.%<br />

The thermodilatometric curve of green samples can be divided into typical parts corresponding<br />

to processes in kaolin and quartz. The liberation of physically bound water at temperatures<br />

from 20 °C to 250 °C leads to more tight contacts between kaolinite crystals and, subsequently,<br />

to the shrinkage of the sample. On the other side, thermal expansion takes place at the same<br />

time which increases the size of the sample. The curve between 20 °C and 250 °C follows from<br />

these two competitive mechanisms. After liberation of the physically bound water, only the<br />

thermal expansion takes place. Dehydroxylation at temperatures from 450 °C to 650 °C is<br />

accompanied by the creation of metakaolinite. Its crystals are of the same type as kaolinite<br />

crystals, but have a smaller c‐parameter, so the shrinkage of the sample can be observed. The α<br />

→ β transformation of quartz takes place at 573 °C. If the quartz grains are free and can change<br />

their dimensions without any obstruction, then their relative volume change is +0.68 %.<br />

However, the quartz grains are not free but surrounded by the kaolin structure. So, the quartz<br />

grains increase their volume less than 0.68 %. The beginning of the solid‐phase sintering also<br />

gives rise to more shrinkage which continues untill the end of heating. The collapse of<br />

metakaolinite and the creation of alumina spinell (metastable phase) and primary mullite takes<br />

place above 950 °C. This new structure significantly increases the shrinkage.<br />

Initially, it is noted that there are significant differences between thermodilatometric curves of<br />

the samples with different content of quartz (see Fig. 1). If the sample contains a larger amount<br />

175