GE Consumer & Industrial - G E Power Controls

GE Consumer & Industrial - G E Power Controls

GE Consumer & Industrial - G E Power Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

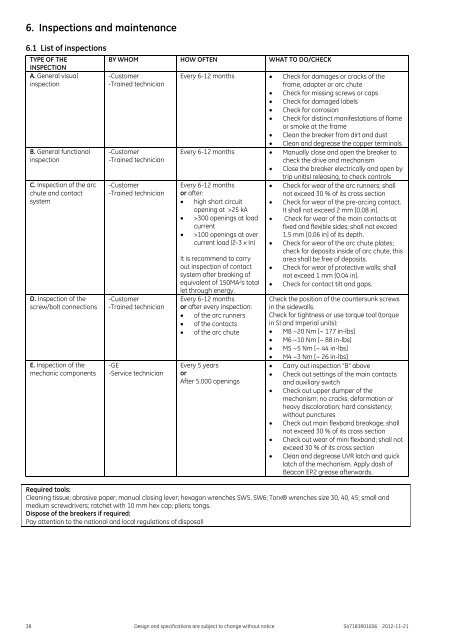

6. Inspections and maintenance<br />

6.1 List of inspections<br />

TYPE OF THE<br />

INSPECTION<br />

A. General visual<br />

inspection<br />

B. General functional<br />

inspection<br />

C. Inspection of the arc<br />

chute and contact<br />

system<br />

D. Inspection of the<br />

screw/bolt connections<br />

E. Inspection of the<br />

mechanic components<br />

BY WHOM HOW OFTEN WHAT TO DO/CHECK<br />

-Customer<br />

-Trained technician<br />

-Customer<br />

-Trained technician<br />

-Customer<br />

-Trained technician<br />

-Customer<br />

-Trained technician<br />

-<strong>GE</strong><br />

-Service technician<br />

Every 6-12 months Check for damages or cracks of the<br />

frame, adapter or arc chute<br />

Check for missing screws or caps<br />

Check for damaged labels<br />

Check for corrosion<br />

Check for distinct manifestations of flame<br />

or smoke at the frame<br />

Clean the breaker from dirt and dust<br />

Clean and degrease the copper terminals<br />

Every 6-12 months Manually close and open the breaker to<br />

check the drive and mechanism<br />

Close the breaker electrically and open by<br />

trip unit(s) releasing, to check controls<br />

Every 6-12 months<br />

Check for wear of the arc runners; shall<br />

or after:<br />

not exceed 30 % of its cross section<br />

high short circuit Check for wear of the pre-arcing contact.<br />

opening at >25 kA<br />

It shall not exceed 2 mm [0.08 in].<br />

>300 openings at load Check for wear of the main contacts at<br />

current<br />

fixed and flexible sides; shall not exceed<br />

>100 openings at over 1.5 mm [0.06 in] of its depth.<br />

current load (2-3 x In) Check for wear of the arc chute plates;<br />

check for deposits inside of arc chute, this<br />

area shall be free of deposits.<br />

It is recommend to carry<br />

out inspection of contact<br />

system after breaking of<br />

equivalent of 150MA 2 s total<br />

let through energy.<br />

Every 6-12 months<br />

or after every inspection:<br />

of the arc runners<br />

of the contacts<br />

of the arc chute<br />

Every 5 years<br />

or<br />

After 5.000 openings<br />

<br />

<br />

Check for wear of protective walls; shall<br />

not exceed 1 mm [0.04 in].<br />

Check for contact tilt and gaps.<br />

Check the position of the countersunk screws<br />

in the sidewalls.<br />

Check for tightness or use torque tool (torque<br />

in SI and Imperial units):<br />

M8 ~20 Nm [~ 177 in-lbs]<br />

M6 ~10 Nm [~ 88 in-lbs]<br />

M5 ~5 Nm [~ 44 in-lbs]<br />

M4 ~3 Nm [~ 26 in-lbs]<br />

Carry out inspection “B” above<br />

Check out settings of the main contacts<br />

and auxiliary switch<br />

Check out upper dumper of the<br />

mechanism; no cracks, deformation or<br />

heavy discoloration; hard consistency;<br />

without punctures<br />

Check out main flexband breakage; shall<br />

not exceed 30 % of its cross section<br />

Check out wear of mini flexband; shall not<br />

exceed 30 % of its cross section<br />

Clean and degrease UVR latch and quick<br />

latch of the mechanism. Apply dash of<br />

Beacon EP2 grease afterwards.<br />

Required tools:<br />

Cleaning tissue; abrasive paper; manual closing lever; hexagon wrenches SW5, SW6; Torx® wrenches size 30, 40, 45; small and<br />

medium screwdrivers; ratchet with 10 mm hex cap; pliers; tongs.<br />

Dispose of the breakers if required:<br />

Pay attention to the national and local regulations of disposal!<br />

38 Design and specifications are subject to change without notice S47183R01E06 2012-11-21