Safe Quarry - Health and Safety Authority

Safe Quarry - Health and Safety Authority

Safe Quarry - Health and Safety Authority

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PART 3<br />

GENERAL SAFETY PROVISIONS<br />

(c) Tyre Changing or repair<br />

There are a number of hazards associated with tyre<br />

changing <strong>and</strong> repair <strong>and</strong> these should all be<br />

addressed prior to any work being carried out:<br />

(i) If a vehicle is to be raised to remove the wheel<br />

then the vehicle must be adequately<br />

supported to prevent any danger of collapse<br />

<strong>and</strong> the operation must be carried out on solid<br />

ground that will not fail resulting in collapse;<br />

(ii) Adequate lifting equipment <strong>and</strong> restraining<br />

equipment must be available to remove the<br />

wheel to be changed or removed <strong>and</strong> the<br />

wheel must never be left free st<strong>and</strong>ing where<br />

there is a danger of it falling <strong>and</strong> causing injury;<br />

(ii) Inflation of tyres should be carried out from a<br />

position of safety <strong>and</strong> where necessary a<br />

suitable tyre cage is required <strong>and</strong> the sidewall<br />

of the tyre should be inspected prior to<br />

inflation to ensure it is not defective;<br />

(iii) After changing or refitting of a wheel the wheel<br />

nuts or clamping devices must be correctly<br />

installed <strong>and</strong> tensioned;<br />

(iv)Tyres <strong>and</strong> wheels which are to be taken off site<br />

for repair or disposal must be stored so that<br />

they will not endanger persons as a result of<br />

collapse; <strong>and</strong><br />

(v) Good st<strong>and</strong>ards of housekeeping should be<br />

maintained.<br />

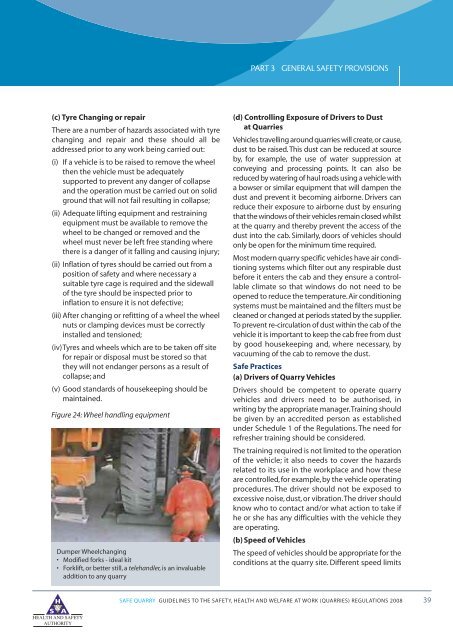

Figure 24: Wheel h<strong>and</strong>ling equipment<br />

Dumper Wheelchanging<br />

• Modified forks - ideal kit<br />

• Forklift, or better still, a teleh<strong>and</strong>ler, is an invaluable<br />

addition to any quarry<br />

(d) Controlling Exposure of Drivers to Dust<br />

at Quarries<br />

Vehicles travelling around quarries will create,or cause,<br />

dust to be raised. This dust can be reduced at source<br />

by, for example, the use of water suppression at<br />

conveying <strong>and</strong> processing points. It can also be<br />

reduced by watering of haul roads using a vehicle with<br />

a bowser or similar equipment that will dampen the<br />

dust <strong>and</strong> prevent it becoming airborne. Drivers can<br />

reduce their exposure to airborne dust by ensuring<br />

that the windows of their vehicles remain closed whilst<br />

at the quarry <strong>and</strong> thereby prevent the access of the<br />

dust into the cab. Similarly, doors of vehicles should<br />

only be open for the minimum time required.<br />

Most modern quarry specific vehicles have air conditioning<br />

systems which filter out any respirable dust<br />

before it enters the cab <strong>and</strong> they ensure a controllable<br />

climate so that windows do not need to be<br />

opened to reduce the temperature.Air conditioning<br />

systems must be maintained <strong>and</strong> the filters must be<br />

cleaned or changed at periods stated by the supplier.<br />

To prevent re-circulation of dust within the cab of the<br />

vehicle it is important to keep the cab free from dust<br />

by good housekeeping <strong>and</strong>, where necessary, by<br />

vacuuming of the cab to remove the dust.<br />

<strong>Safe</strong> Practices<br />

(a) Drivers of <strong>Quarry</strong> Vehicles<br />

Drivers should be competent to operate quarry<br />

vehicles <strong>and</strong> drivers need to be authorised, in<br />

writing by the appropriate manager.Training should<br />

be given by an accredited person as established<br />

under Schedule 1 of the Regulations. The need for<br />

refresher training should be considered.<br />

The training required is not limited to the operation<br />

of the vehicle; it also needs to cover the hazards<br />

related to its use in the workplace <strong>and</strong> how these<br />

are controlled, for example, by the vehicle operating<br />

procedures. The driver should not be exposed to<br />

excessive noise, dust, or vibration.The driver should<br />

know who to contact <strong>and</strong>/or what action to take if<br />

he or she has any difficulties with the vehicle they<br />

are operating.<br />

(b) Speed of Vehicles<br />

The speed of vehicles should be appropriate for the<br />

conditions at the quarry site. Different speed limits<br />

SAFE QUARRY GUIDELINES TO THE SAFETY, HEALTH AND WELFARE AT WORK (QUARRIES) REGULATIONS 2008 39