REVISTA ROMÃNÄ DE AUTOMATICÄ - IPA SA

REVISTA ROMÃNÄ DE AUTOMATICÄ - IPA SA

REVISTA ROMÃNÄ DE AUTOMATICÄ - IPA SA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36<br />

<strong>REVISTA</strong> ROMÂNĂ <strong>DE</strong> AUTOMATICĂ<br />

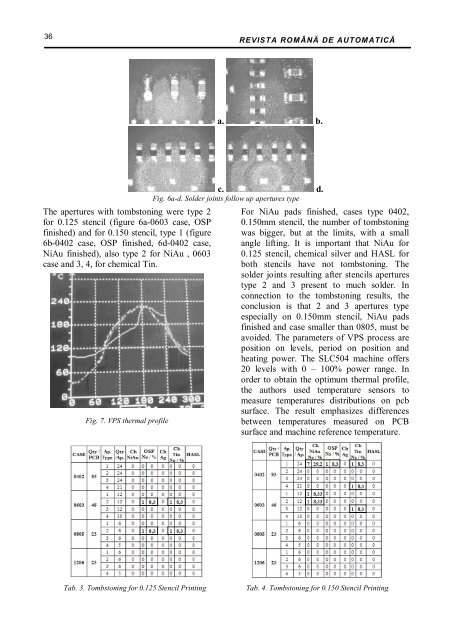

a. b.<br />

The apertures with tombstoning were type 2<br />

for 0.125 stencil (figure 6a-0603 case, OSP<br />

finished) and for 0.150 stencil, type 1 (figure<br />

6b-0402 case, OSP finished, 6d-0402 case,<br />

NiAu finished), also type 2 for NiAu , 0603<br />

case and 3, 4, for chemical Tin.<br />

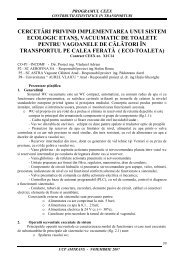

Fig. 7. VPS thermal profile<br />

c. d.<br />

Fig. 6a-d. Solder joints follow up apertures type<br />

For NiAu pads finished, cases type 0402,<br />

0.150mm stencil, the number of tombstoning<br />

was bigger, but at the limits, with a small<br />

angle lifting. It is important that NiAu for<br />

0.125 stencil, chemical silver and HASL for<br />

both stencils have not tombstoning. The<br />

solder joints resulting after stencils apertures<br />

type 2 and 3 present to much solder. In<br />

connection to the tombstoning results, the<br />

conclusion is that 2 and 3 apertures type<br />

especially on 0.150mm stencil, NiAu pads<br />

finished and case smaller than 0805, must be<br />

avoided. The parameters of VPS process are<br />

position on levels, period on position and<br />

heating power. The SLC504 machine offers<br />

20 levels with 0 – 100% power range. In<br />

order to obtain the optimum thermal profile,<br />

the authors used temperature sensors to<br />

measure temperatures distributions on pcb<br />

surface. The result emphasizes differences<br />

between temperatures measured on PCB<br />

surface and machine reference temperature.<br />

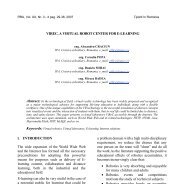

Tab. 3. Tombstoning for 0.125 Stencil Printing<br />

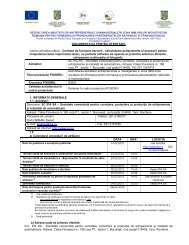

Tab. 4. Tombstoning for 0.150 Stencil Printing