guide to thin section microscopy - Mineralogical Society of America

guide to thin section microscopy - Mineralogical Society of America

guide to thin section microscopy - Mineralogical Society of America

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

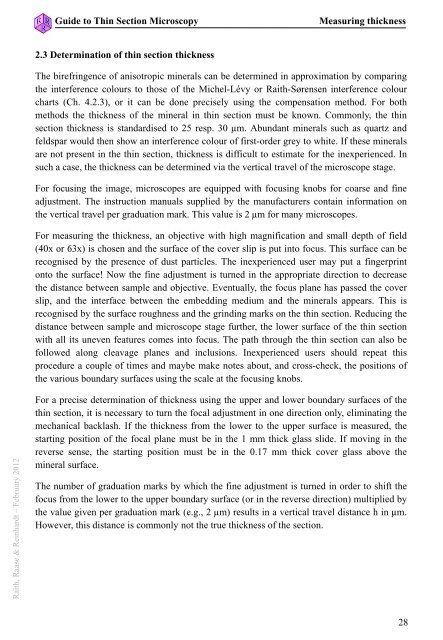

Guide <strong>to</strong> Thin Section Microscopy<br />

Measuring thickness<br />

2.3 Determination <strong>of</strong> <strong>thin</strong> <strong>section</strong> thickness<br />

The birefringence <strong>of</strong> anisotropic minerals can be determined in approximation by comparing<br />

the interference colours <strong>to</strong> those <strong>of</strong> the Michel-Lévy or Raith-Sørensen interference colour<br />

charts (Ch. 4.2.3), or it can be done precisely using the compensation method. For both<br />

methods the thickness <strong>of</strong> the mineral in <strong>thin</strong> <strong>section</strong> must be known. Commonly, the <strong>thin</strong><br />

<strong>section</strong> thickness is standardised <strong>to</strong> 25 resp. 30 μm. Abundant minerals such as quartz and<br />

feldspar would then show an interference colour <strong>of</strong> first-order grey <strong>to</strong> white. If these minerals<br />

are not present in the <strong>thin</strong> <strong>section</strong>, thickness is difficult <strong>to</strong> estimate for the inexperienced. In<br />

such a case, the thickness can be determined via the vertical travel <strong>of</strong> the microscope stage.<br />

For focusing the image, microscopes are equipped with focusing knobs for coarse and fine<br />

adjustment. The instruction manuals supplied by the manufacturers contain information on<br />

the vertical travel per graduation mark. This value is 2 μm for many microscopes.<br />

For measuring the thickness, an objective with high magnification and small depth <strong>of</strong> field<br />

(40x or 63x) is chosen and the surface <strong>of</strong> the cover slip is put in<strong>to</strong> focus. This surface can be<br />

recognised by the presence <strong>of</strong> dust particles. The inexperienced user may put a fingerprint<br />

on<strong>to</strong> the surface! Now the fine adjustment is turned in the appropriate direction <strong>to</strong> decrease<br />

the distance between sample and objective. Eventually, the focus plane has passed the cover<br />

slip, and the interface between the embedding medium and the minerals appears. This is<br />

recognised by the surface roughness and the grinding marks on the <strong>thin</strong> <strong>section</strong>. Reducing the<br />

distance between sample and microscope stage further, the lower surface <strong>of</strong> the <strong>thin</strong> <strong>section</strong><br />

with all its uneven features comes in<strong>to</strong> focus. The path through the <strong>thin</strong> <strong>section</strong> can also be<br />

followed along cleavage planes and inclusions. Inexperienced users should repeat this<br />

procedure a couple <strong>of</strong> times and maybe make notes about, and cross-check, the positions <strong>of</strong><br />

the various boundary surfaces using the scale at the focusing knobs.<br />

Raith, Raase & Reinhardt – February 2012<br />

For a precise determination <strong>of</strong> thickness using the upper and lower boundary surfaces <strong>of</strong> the<br />

<strong>thin</strong> <strong>section</strong>, it is necessary <strong>to</strong> turn the focal adjustment in one direction only, eliminating the<br />

mechanical backlash. If the thickness from the lower <strong>to</strong> the upper surface is measured, the<br />

starting position <strong>of</strong> the focal plane must be in the 1 mm thick glass slide. If moving in the<br />

reverse sense, the starting position must be in the 0.17 mm thick cover glass above the<br />

mineral surface.<br />

The number <strong>of</strong> graduation marks by which the fine adjustment is turned in order <strong>to</strong> shift the<br />

focus from the lower <strong>to</strong> the upper boundary surface (or in the reverse direction) multiplied by<br />

the value given per graduation mark (e.g., 2 μm) results in a vertical travel distance h in μm.<br />

However, this distance is commonly not the true thickness <strong>of</strong> the <strong>section</strong>.<br />

28