safety - PKN Orlen

safety - PKN Orlen

safety - PKN Orlen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Corporate responsibility report<br />

In order to increase the output of the most valuable<br />

products (depending on the current market situation),<br />

the Production Plant in Płock implements advanced<br />

process control systems.<br />

In the autumn of 2010, the Company completed<br />

the construction of a modern heat recovery steam boiler<br />

at the Fluid Catalytic Cracking II (FKKII) unit for technological<br />

gas cooling. The energy recovered in this way<br />

is used to produce 4 MPa technological steam.<br />

The Company has independently developed several<br />

tools to monitor certain key indexes such as: EII energy<br />

index, MA (mechanical availability index), OA (operational<br />

availability) index, PU (plant use) index. Data collected<br />

in this way is used for ongoing operational assessment<br />

of used assets. It is also an indicator to be considered<br />

in current and future decisions. These activities form a part<br />

of the Company’s Fuel Studies conducted by Solomon<br />

Associates, which are aimed at assessing the Company<br />

from the perspective of competitiveness on the world<br />

refinery market.<br />

Pro-environmental effects in terms of fuel production<br />

All types of petrol produced at <strong>PKN</strong> ORLEN contain<br />

a combination r mo e in r of a the io best visit quality purifying additives,<br />

whose main component is a detergent that guarantees<br />

compliance with the highest criteria of intake valve<br />

a ,<br />

cleanliness established in the World-Wide Fuel Charter.<br />

For more information, visit:<br />

The 2009 Corporate Responsibility Report, pp. 51 – 52<br />

In late November 2010, the Company launched<br />

the production of a new type of base petrol containing<br />

1.2 %(V/V) of a bio-component: ethyl tert-butyl<br />

e n m t , v<br />

ether [BB95E1.2] compliant with the corporate standard<br />

ZN-ORLEN 43:2010, and alcohol petrol ES95A 4.8 E 1.2<br />

on the basis of the same standard, compliant with<br />

the PN-EN 228:2008 standard and the Regulation<br />

of the Polish Minister of Economy of 9 December 2008.<br />

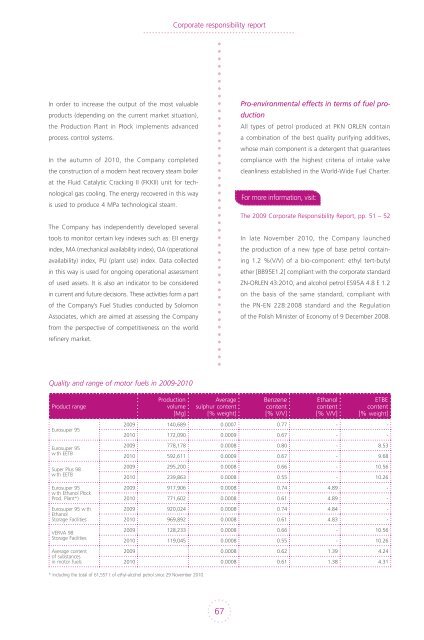

Quality and range of motor fuels in 2009-2010<br />

Product range<br />

Eurosuper 95<br />

Eurosuper 95<br />

w th EETB<br />

Super Plus 98<br />

w th EETB<br />

Eurosuper 95<br />

w th Ethanol Płock<br />

Prod. Plant*)<br />

Eurosuper 95 w th<br />

Ethanol<br />

Storage Facilities<br />

VERVA 98<br />

Storage Facilities<br />

Average content<br />

of substances<br />

in motor fuels<br />

Production<br />

volume<br />

[Mg]<br />

Average<br />

sulphur content<br />

[% weight]<br />

Benzene<br />

content<br />

[% V/V]<br />

Ethanol<br />

content<br />

[% V/V]<br />

ETBE<br />

content<br />

[% weight]<br />

2009 140,689 0.0007 0.77 - -<br />

2010 172,090 0.0009 0.67 - -<br />

2009 778,178 0.0008 0.80 - 8.53<br />

2010 592,611 0.0009 0.67 - 9.68<br />

2009 295,200 0.0008 0.66 - 10.56<br />

2010 239,863 0.0008 0.55 - 10.26<br />

2009 917,906 0.0008 0.74 4.89 -<br />

2010 771,602 0.0008 0.61 4.89 -<br />

2009 920,024 0.0008 0.74 4.84 -<br />

2010 969,892 0.0008 0.61 4.83 -<br />

2009 128,233 0.0008 0.66 - 10.56<br />

2010 119,045 0.0008 0.55 - 10.26<br />

2009 0.0008 0.62 1.39 4.24<br />

2010 0.0008 0.61 1.38 4.31<br />

* Including the total of 61,557 t of ethyl-alcohol petrol since 29 November 2010.<br />

67