Annual Report 2006 - Plataforma Solar de AlmerÃa

Annual Report 2006 - Plataforma Solar de AlmerÃa

Annual Report 2006 - Plataforma Solar de AlmerÃa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

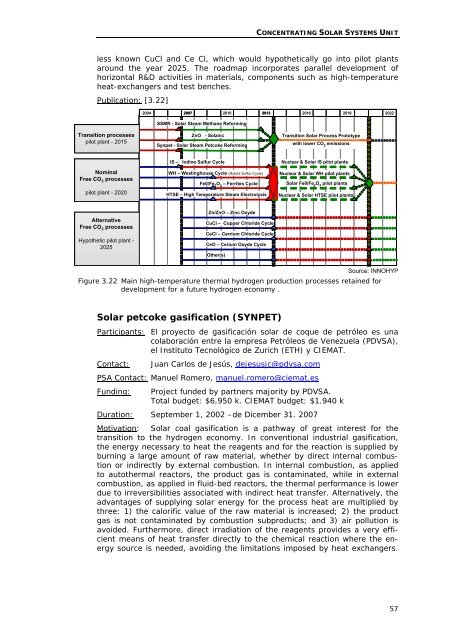

CONCENTRATING SOLAR SYSTEMS UNIT<br />

less known CuCl and Ce Cl, which would hypothetically go into pilot plants<br />

around the year 2025. The roadmap incorporates parallel <strong>de</strong>velopment of<br />

horizontal R&D activities in materials, components such as high-temperature<br />

heat-exchangers and test benches.<br />

Publication: [3.22]<br />

2004<br />

2007<br />

2010<br />

2013<br />

2016<br />

2019<br />

2022<br />

Transition processes<br />

pilot plant - 2015<br />

SSMR - <strong>Solar</strong> Steam Methane Reforming<br />

ZnO<br />

- Solzinc<br />

Synpet - <strong>Solar</strong> Steam Petcoke Reforming<br />

Transition <strong>Solar</strong> Process Prototype<br />

with lower CO 2 emissions<br />

Nominal<br />

Free CO 2 processes<br />

pilot plant - 2020<br />

IS –<br />

Iodine Sulfur Cycle<br />

WH – Westinghouse Cycle (Hybrid Sulfur Cycle)<br />

Fe0/Fe 2 O 3 –Ferrites Cycle<br />

HTSE – High Temperature Steam Electrolysis<br />

Nuclear & <strong>Solar</strong> IS pilot plants<br />

Nuclear & <strong>Solar</strong> WH pilot plants<br />

<strong>Solar</strong> Fe0/Fe 2 O 3 pilot plants<br />

Nuclear & <strong>Solar</strong> HTSE pilot plants<br />

Alternative<br />

Free CO 2 processes<br />

Hypothetic pilot plant -<br />

2025<br />

Zn/ZnO – Zinc Oxy<strong>de</strong><br />

CuCl – Cupper Chlori<strong>de</strong> Cycle<br />

CeCl – Cerrium Chlori<strong>de</strong> Cycle<br />

CeO – Cerium Oxy<strong>de</strong> Cycle<br />

Other(s)<br />

Source: INNOHYP<br />

Figure 3.22 Main high-temperature thermal hydrogen production processes retained for<br />

<strong>de</strong>velopment for a future hydrogen economy .<br />

<strong>Solar</strong> petcoke gasification (SYNPET)<br />

Participants: El proyecto <strong>de</strong> gasificación solar <strong>de</strong> coque <strong>de</strong> petróleo es una<br />

colaboración entre la empresa Petróleos <strong>de</strong> Venezuela (PDVSA),<br />

el Instituto Tecnológico <strong>de</strong> Zurich (ETH) y CIEMAT.<br />

Contact:<br />

Juan Carlos <strong>de</strong> Jesús, <strong>de</strong>jesusjc@pdvsa.com<br />

PSA Contact: Manuel Romero, manuel.romero@ciemat.es<br />

Funding:<br />

Project fun<strong>de</strong>d by partners majority by PDVSA.<br />

Total budget: $6,950 k. CIEMAT budget: $1.940 k<br />

Duration: September 1, 2002 –<strong>de</strong> Dicember 31. 2007<br />

Motivation: <strong>Solar</strong> coal gasification is a pathway of great interest for the<br />

transition to the hydrogen economy. In conventional industrial gasification,<br />

the energy necessary to heat the reagents and for the reaction is supplied by<br />

burning a large amount of raw material, whether by direct internal combustion<br />

or indirectly by external combustion. In internal combustion, as applied<br />

to autothermal reactors, the product gas is contaminated, while in external<br />

combustion, as applied in fluid-bed reactors, the thermal performance is lower<br />

due to irreversibilities associated with indirect heat transfer. Alternatively, the<br />

advantages of supplying solar energy for the process heat are multiplied by<br />

three: 1) the calorific value of the raw material is increased; 2) the product<br />

gas is not contaminated by combustion subproducts; and 3) air pollution is<br />

avoi<strong>de</strong>d. Furthermore, direct irradiation of the reagents provi<strong>de</strong>s a very efficient<br />

means of heat transfer directly to the chemical reaction where the energy<br />

source is nee<strong>de</strong>d, avoiding the limitations imposed by heat exchangers.<br />

57