industry and environment - DTIE

industry and environment - DTIE

industry and environment - DTIE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chemicals management<br />

Liquid waste<br />

Wastewater quality <strong>and</strong> quantity vary considerably<br />

(e.g. wastewater per tonne of dye produced is<br />

very low compared with wastewater per tonne of<br />

dye intermediate produced). In the case of major<br />

dye intermediates, specific wastewater generation<br />

is about 15-20 m 3 /tonne of product. The main<br />

sources of wastewater generation are:<br />

◆ mother liquor or filtrate streams from filtration<br />

operations;<br />

◆ wastewater streams from washing of filter cake<br />

to remove salt impurities or residual filtrate adhering<br />

to the cake;<br />

◆ leakage <strong>and</strong> spillage;<br />

◆ floor washing in the work area.<br />

Typical characteristics of wastewater from this<br />

sector are shown in Table 1.<br />

Effluent discharged from this sector is highly<br />

acidic. It contains toxic compounds, many of<br />

which are carcinogenic. They can be very hazardous<br />

to human health <strong>and</strong> the <strong>environment</strong>.<br />

This is due to the presence in the wastewater of<br />

benzene, naphthalene, <strong>and</strong> other nitro-aromatic<br />

based compounds used as raw material in the production<br />

of dye intermediates. Due to excessive<br />

acid <strong>and</strong> alkali use, the wastewater also contains<br />

high concentrations of inorganic salts, resulting in<br />

high concentrations of total dissolved solids<br />

(TDS). Because of the high level of TDS <strong>and</strong> toxic<br />

aromatic compounds, effluent treatment is very<br />

difficult <strong>and</strong> expensive.<br />

Under the regulations prevailing in India, there<br />

is currently no <strong>industry</strong>-specific effluent st<strong>and</strong>ard<br />

for the dye <strong>industry</strong>. The general st<strong>and</strong>ard therefore<br />

applies. According to this st<strong>and</strong>ard, effluent<br />

discharged by an industrial unit must meet the<br />

parameters in Table 2.<br />

Management of liquid waste<br />

Before 1994, many small <strong>and</strong> medium-sized units<br />

in this sector did not treat their wastewater. It was<br />

discharged directly to nearby surface water. Large<br />

units <strong>and</strong> some medium-sized ones carried out<br />

primary treatment, but almost none of these units<br />

met pollution norms.<br />

Following strict regulatory action, <strong>and</strong> intervention<br />

by the High Court <strong>and</strong> Supreme Court,<br />

industries began detailed wastewater treatment.<br />

Today all units carry out primary wastewater treatment;<br />

some also have secondary <strong>and</strong> tertiary treatment<br />

systems. Nevertheless, it is still impossible<br />

to meet the prescribed Pollution Control Board<br />

norms. The reasons for this are:<br />

◆Industrial units (especially if they are small-scale)<br />

do not have enough l<strong>and</strong> area to construct a treatment<br />

plant with a capacity of about 50,000-<br />

100,000 litres/day. Most plants are underdesigned;<br />

◆ Treatment costs are very high. Units that are<br />

small-scale economically cannot afford treatment;<br />

◆ The wastewater is very difficult to treat;<br />

◆ The expertise needed for proper treatment is not<br />

available locally;<br />

◆ Frequent product changes (based on dem<strong>and</strong>)<br />

<strong>and</strong> poor process control at the production plant<br />

change effluent characteristics over time, thus disturbing<br />

the treatment system.<br />

End-of-pipe (EOP) treatment is a control strategy<br />

to protect the <strong>environment</strong> from the<br />

impact of waste <strong>and</strong> emissions discharged from<br />

industries. The EOP treatment strategy incorporates<br />

treatment of the waste <strong>and</strong> emissions<br />

generated to bring them to a particular level<br />

(considering the assimilative capacity of the<br />

receiving bodies) before discharge. The EOP<br />

strategy has existed since the establishment of<br />

India’s Pollution Control Boards <strong>and</strong> the introduction<br />

of the Air <strong>and</strong> Water Pollution Prevention<br />

<strong>and</strong> Control Acts.<br />

The Government <strong>and</strong> Industry Associations<br />

have decided to build common effluent treatment<br />

plants (CETPs) for primary-treated industrial<br />

wastewater. The government has also taken steps<br />

to fund the CETP projects, 3 as well as research<br />

aimed at reviving the use of natural dyes, extension<br />

of MODVAT 4 benefits to pollution control<br />

equipment <strong>and</strong> other activities. It has also initiated<br />

a ban on 190 textile dyes (in view of the German<br />

ban on azo dyes) <strong>and</strong> emphasis is being given<br />

to substitute dyes. Similarly to the CETP initiative,<br />

steps need to be taken in the DDI <strong>industry</strong><br />

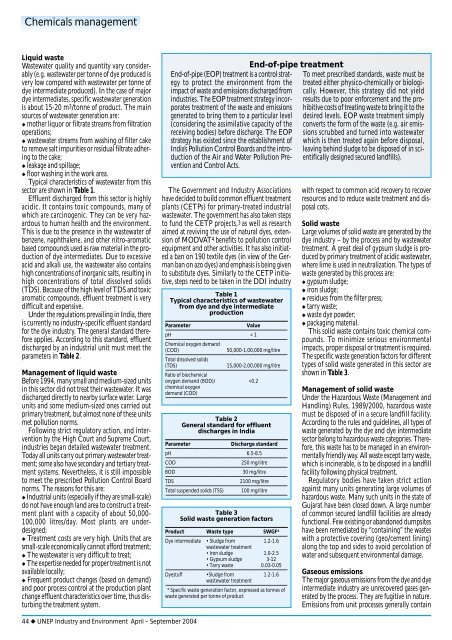

Table 1<br />

Typical characteristics of wastewater<br />

from dye <strong>and</strong> dye intermediate<br />

production<br />

Parameter<br />

Value<br />

pH < 1<br />

Chemical oxygen dem<strong>and</strong><br />

(COD)<br />

50,000-1,00,000 mg/litre<br />

Total dissolved solids<br />

(TDS)<br />

15,000-2,00,000 mg/litre<br />

Ratio of biochemical<br />

oxygen dem<strong>and</strong> (BOD)/