The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DSTO-RR-0208<br />

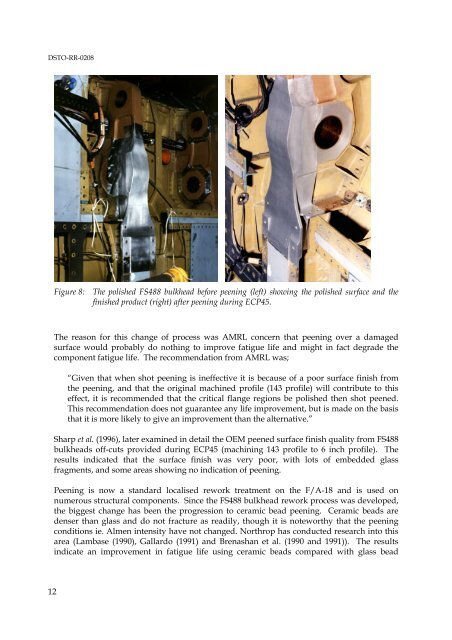

Figure 8:<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> polished FS488 bulkhead before peening (left) showing <strong>the</strong> polished surface and <strong>the</strong><br />

finished product (right) after peening during ECP45.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> reas<strong>on</strong> for this change <str<strong>on</strong>g>of</str<strong>on</strong>g> process was AMRL c<strong>on</strong>cern that peening over a damaged<br />

surface would probably do nothing to improve fatigue life and might in fact degrade <strong>the</strong><br />

comp<strong>on</strong>ent fatigue life. <str<strong>on</strong>g>The</str<strong>on</strong>g> recommendati<strong>on</strong> from AMRL was;<br />

“Given that when shot peening is ineffective it is because <str<strong>on</strong>g>of</str<strong>on</strong>g> a poor surface finish from<br />

<strong>the</strong> peening, and that <strong>the</strong> original machined pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile (143 pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile) will c<strong>on</strong>tribute to this<br />

effect, it is recommended that <strong>the</strong> critical flange regi<strong>on</strong>s be polished <strong>the</strong>n shot peened.<br />

This recommendati<strong>on</strong> does not guarantee any life improvement, but is made <strong>on</strong> <strong>the</strong> basis<br />

that it is more likely to give an improvement than <strong>the</strong> alternative.”<br />

Sharp et al. (1996), later examined in detail <strong>the</strong> OEM peened surface finish quality from FS488<br />

bulkheads <str<strong>on</strong>g>of</str<strong>on</strong>g>f-cuts provided during ECP45 (machining 143 pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile to 6 inch pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile). <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

results indicated that <strong>the</strong> surface finish was very poor, with lots <str<strong>on</strong>g>of</str<strong>on</strong>g> embedded glass<br />

fragments, and some areas showing no indicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> peening.<br />

<str<strong>on</strong>g>Peening</str<strong>on</strong>g> is now a standard localised rework treatment <strong>on</strong> <strong>the</strong> F/A-18 and is used <strong>on</strong><br />

numerous structural comp<strong>on</strong>ents. Since <strong>the</strong> FS488 bulkhead rework process was developed,<br />

<strong>the</strong> biggest change has been <strong>the</strong> progressi<strong>on</strong> to ceramic bead peening. Ceramic beads are<br />

denser than glass and do not fracture as readily, though it is noteworthy that <strong>the</strong> peening<br />

c<strong>on</strong>diti<strong>on</strong>s ie. Almen intensity have not changed. Northrop has c<strong>on</strong>ducted research into this<br />

area (Lambase (1990), Gallardo (1991) and Brenashan et al. (1990 and 1991)). <str<strong>on</strong>g>The</str<strong>on</strong>g> results<br />

indicate an improvement in fatigue life using ceramic beads compared with glass bead<br />

12