The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DSTO-RR-0208<br />

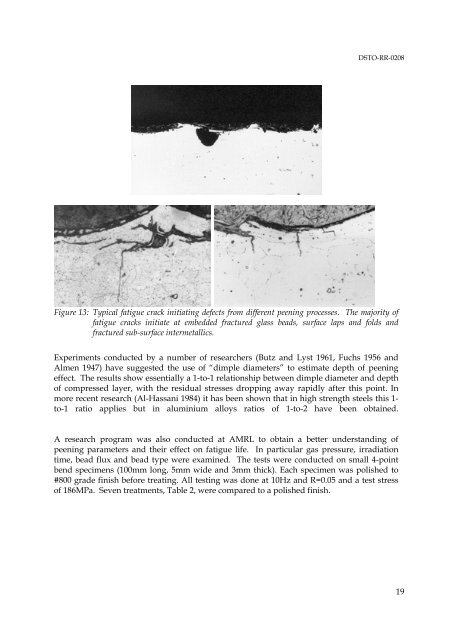

Figure 13: Typical fatigue crack initiating defects from different peening processes. <str<strong>on</strong>g>The</str<strong>on</strong>g> majority <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

fatigue cracks initiate at embedded fractured glass beads, surface laps and folds and<br />

fractured sub-surface intermetallics.<br />

Experiments c<strong>on</strong>ducted by a number <str<strong>on</strong>g>of</str<strong>on</strong>g> researchers (Butz and Lyst 1961, Fuchs 1956 and<br />

Almen 1947) have suggested <strong>the</strong> use <str<strong>on</strong>g>of</str<strong>on</strong>g> “dimple diameters” to estimate depth <str<strong>on</strong>g>of</str<strong>on</strong>g> peening<br />

effect. <str<strong>on</strong>g>The</str<strong>on</strong>g> results show essentially a 1-to-1 relati<strong>on</strong>ship between dimple diameter and depth<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> compressed layer, with <strong>the</strong> residual stresses dropping away rapidly after this point. In<br />

more recent research (Al-Hassani 1984) it has been shown that in high strength steels this 1-<br />

to-1 ratio applies but in aluminium alloys ratios <str<strong>on</strong>g>of</str<strong>on</strong>g> 1-to-2 have been obtained.<br />

A research program was also c<strong>on</strong>ducted at AMRL to obtain a better understanding <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

peening parameters and <strong>the</strong>ir effect <strong>on</strong> fatigue life. In particular gas pressure, irradiati<strong>on</strong><br />

time, bead flux and bead type were examined. <str<strong>on</strong>g>The</str<strong>on</strong>g> tests were c<strong>on</strong>ducted <strong>on</strong> small 4-point<br />

bend specimens (100mm l<strong>on</strong>g, 5mm wide and 3mm thick). Each specimen was polished to<br />

#800 grade finish before treating. All testing was d<strong>on</strong>e at 10Hz and R=0.05 and a test stress<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> 186MPa. Seven treatments, Table 2, were compared to a polished finish.<br />

19