The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DSTO-RR-0208<br />

Peak Spectrum Stress (MPa)<br />

420<br />

415<br />

410<br />

405<br />

400<br />

395<br />

390<br />

385<br />

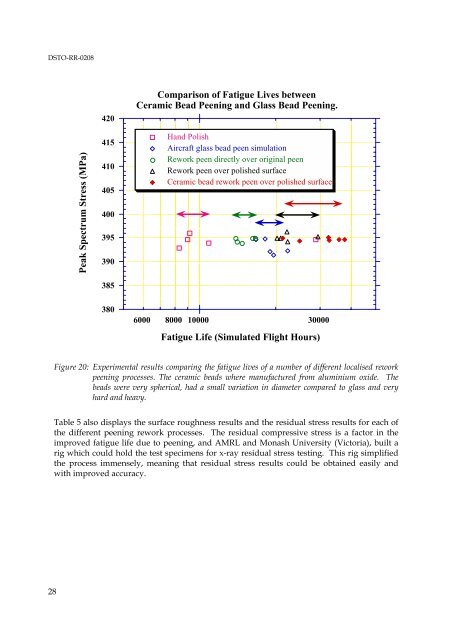

Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Fatigue</strong> Lives between<br />

Ceramic Bead <str<strong>on</strong>g>Peening</str<strong>on</strong>g> and Glass Bead <str<strong>on</strong>g>Peening</str<strong>on</strong>g>.<br />

Hand Polish<br />

Aircraft glass bead peen simulati<strong>on</strong><br />

Rework peen directly over original peen<br />

Rework peen over polished surface<br />

Ceramic bead rework peen over polished surface<br />

380<br />

6000 8000 10000 30000<br />

<strong>Fatigue</strong> <strong>Life</strong> (Simulated Flight Hours)<br />

Figure 20: Experimental results comparing <strong>the</strong> fatigue lives <str<strong>on</strong>g>of</str<strong>on</strong>g> a number <str<strong>on</strong>g>of</str<strong>on</strong>g> different localised rework<br />

peening processes. <str<strong>on</strong>g>The</str<strong>on</strong>g> ceramic beads where manufactured from aluminium oxide. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

beads were very spherical, had a small variati<strong>on</strong> in diameter compared to glass and very<br />

hard and heavy.<br />

Table 5 also displays <strong>the</strong> surface roughness results and <strong>the</strong> residual stress results for each <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> different peening rework processes. <str<strong>on</strong>g>The</str<strong>on</strong>g> residual compressive stress is a factor in <strong>the</strong><br />

improved fatigue life due to peening, and AMRL and M<strong>on</strong>ash University (Victoria), built a<br />

rig which could hold <strong>the</strong> test specimens for x-ray residual stress testing. This rig simplified<br />

<strong>the</strong> process immensely, meaning that residual stress results could be obtained easily and<br />

with improved accuracy.<br />

28