The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DSTO-RR-0208<br />

Table 5:<br />

Results from local peening rework processes. <str<strong>on</strong>g>The</str<strong>on</strong>g> OEM rework – peen over OEM original<br />

peen, AMRL rework – remove OEM original peen by polishing <strong>the</strong>n peen. Specimens<br />

(Sharp, Clayt<strong>on</strong> and Clark (1994)) were tested with a RAAF post-LEX spectrum Spec 16 -<br />

21010 turning points 302.9 hrs per block at a peak stress 410 MPa. Material was 5 inch<br />

plate,<br />

Rework Process Log Av. <strong>Fatigue</strong> Surface Roughness Surface Roughness Residual Stress<br />

<strong>Life</strong> (SFH)<br />

R max (µm)<br />

R z (µm)<br />

MPa<br />

Hand polish (#800) 9287 3.4 2.9 -35±20<br />

Simulated original 19079 63.9 46.5 -270±40<br />

aircraft peen<br />

“Overpeen” rework 15073 51.7 38.0 -230±40<br />

AMRL rework<br />

specificati<strong>on</strong><br />

22895 28.2 21.4 -260±40<br />

Table 5 shows that <strong>the</strong> residual compressive stress is very similar no matter which treatment<br />

is used - in o<strong>the</strong>r words <strong>the</strong>y all have reached saturati<strong>on</strong>. Interestingly, in all <strong>the</strong> x-ray<br />

residual stress analyses completed, <strong>the</strong> residual compressive stress range is between -<br />

230MPa and -270MPa. <str<strong>on</strong>g>The</str<strong>on</strong>g> ranking order is very similar to <strong>the</strong> order presented in Table 4,<br />

which were fatigue tests, c<strong>on</strong>ducted using a different spectrum ST-16.<br />

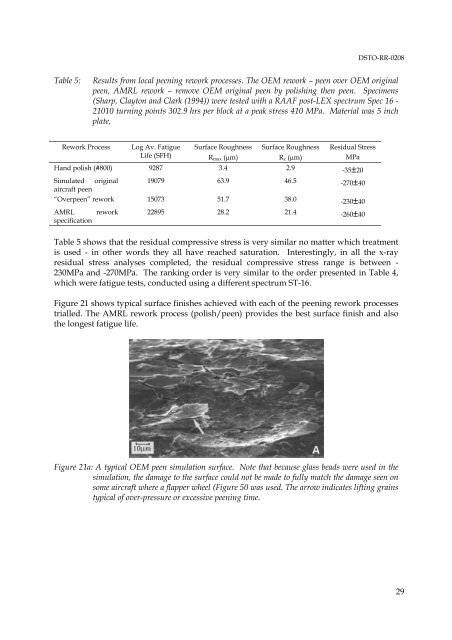

Figure 21 shows typical surface finishes achieved with each <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> peening rework processes<br />

trialled. <str<strong>on</strong>g>The</str<strong>on</strong>g> AMRL rework process (polish/peen) provides <strong>the</strong> best surface finish and also<br />

<strong>the</strong> l<strong>on</strong>gest fatigue life.<br />

Figure 21a: A typical OEM peen simulati<strong>on</strong> surface. Note that because glass beads were used in <strong>the</strong><br />

simulati<strong>on</strong>, <strong>the</strong> damage to <strong>the</strong> surface could not be made to fully match <strong>the</strong> damage seen <strong>on</strong><br />

some aircraft where a flapper wheel (Figure 50 was used. <str<strong>on</strong>g>The</str<strong>on</strong>g> arrow indicates lifting grains<br />

typical <str<strong>on</strong>g>of</str<strong>on</strong>g> over-pressure or excessive peening time.<br />

29