The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DSTO-RR-0208<br />

420MPa 390MPa 330MPa<br />

Depth <str<strong>on</strong>g>of</str<strong>on</strong>g> Material to be Removed<br />

(mm)<br />

10.00<br />

1.00<br />

0.10<br />

0.01<br />

0 2000 4000 6000 8000 10000<br />

Simulated Flight Hours (SFH)<br />

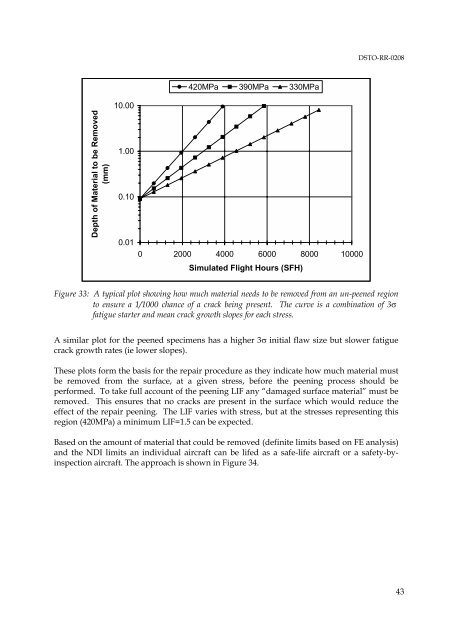

Figure 33: A typical plot showing how much material needs to be removed from an un-peened regi<strong>on</strong><br />

to ensure a 1/1000 chance <str<strong>on</strong>g>of</str<strong>on</strong>g> a crack being present. <str<strong>on</strong>g>The</str<strong>on</strong>g> curve is a combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> 3σ<br />

fatigue starter and mean crack growth slopes for each stress.<br />

A similar plot for <strong>the</strong> peened specimens has a higher 3σ initial flaw size but slower fatigue<br />

crack growth rates (ie lower slopes).<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>se plots form <strong>the</strong> basis for <strong>the</strong> repair procedure as <strong>the</strong>y indicate how much material must<br />

be removed from <strong>the</strong> surface, at a given stress, before <strong>the</strong> peening process should be<br />

performed. To take full account <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> peening LIF any “damaged surface material” must be<br />

removed. This ensures that no cracks are present in <strong>the</strong> surface which would reduce <strong>the</strong><br />

effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> repair peening. <str<strong>on</strong>g>The</str<strong>on</strong>g> LIF varies with stress, but at <strong>the</strong> stresses representing this<br />

regi<strong>on</strong> (420MPa) a minimum LIF=1.5 can be expected.<br />

Based <strong>on</strong> <strong>the</strong> amount <str<strong>on</strong>g>of</str<strong>on</strong>g> material that could be removed (definite limits based <strong>on</strong> FE analysis)<br />

and <strong>the</strong> NDI limits an individual aircraft can be lifed as a safe-life aircraft or a safety-byinspecti<strong>on</strong><br />

aircraft. <str<strong>on</strong>g>The</str<strong>on</strong>g> approach is shown in Figure 34.<br />

43