The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DSTO-RR-0208<br />

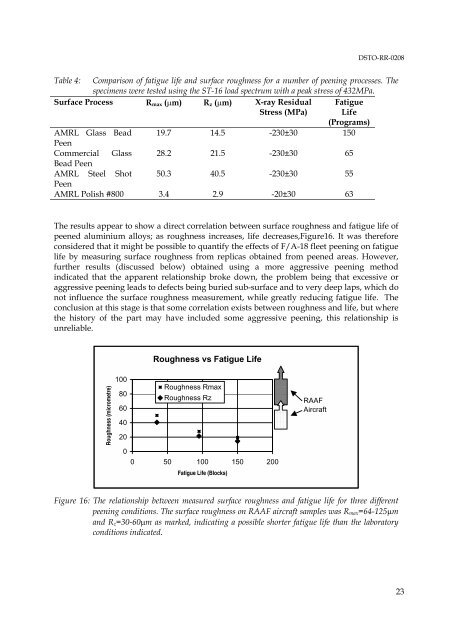

Table 4: Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> fatigue life and surface roughness for a number <str<strong>on</strong>g>of</str<strong>on</strong>g> peening processes. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

specimens were tested using <strong>the</strong> ST-16 load spectrum with a peak stress <str<strong>on</strong>g>of</str<strong>on</strong>g> 432MPa.<br />

Surface Process R max (µm) R z (µm) X-ray Residual<br />

Stress (MPa)<br />

<strong>Fatigue</strong><br />

<strong>Life</strong><br />

(Programs)<br />

AMRL Glass Bead 19.7 14.5 -230±30 150<br />

Peen<br />

Commercial Glass 28.2 21.5 -230±30 65<br />

Bead Peen<br />

AMRL Steel Shot 50.3 40.5 -230±30 55<br />

Peen<br />

AMRL Polish #800 3.4 2.9 -20±30 63<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> results appear to show a direct correlati<strong>on</strong> between surface roughness and fatigue life <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

peened aluminium alloys; as roughness increases, life decreases,Figure16. It was <strong>the</strong>refore<br />

c<strong>on</strong>sidered that it might be possible to quantify <strong>the</strong> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> F/A-18 fleet peening <strong>on</strong> fatigue<br />

life by measuring surface roughness from replicas obtained from peened areas. However,<br />

fur<strong>the</strong>r results (discussed below) obtained using a more aggressive peening method<br />

indicated that <strong>the</strong> apparent relati<strong>on</strong>ship broke down, <strong>the</strong> problem being that excessive or<br />

aggressive peening leads to defects being buried sub-surface and to very deep laps, which do<br />

not influence <strong>the</strong> surface roughness measurement, while greatly reducing fatigue life. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

c<strong>on</strong>clusi<strong>on</strong> at this stage is that some correlati<strong>on</strong> exists between roughness and life, but where<br />

<strong>the</strong> history <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> part may have included some aggressive peening, this relati<strong>on</strong>ship is<br />

unreliable.<br />

Roughness vs <strong>Fatigue</strong> <strong>Life</strong><br />

Roughness (micrometre)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Roughness Rmax<br />

Roughness Rz<br />

0 50 100 150 200<br />

<strong>Fatigue</strong> <strong>Life</strong> (Blocks)<br />

RAAF<br />

Aircraft<br />

Figure 16: <str<strong>on</strong>g>The</str<strong>on</strong>g> relati<strong>on</strong>ship between measured surface roughness and fatigue life for three different<br />

peening c<strong>on</strong>diti<strong>on</strong>s. <str<strong>on</strong>g>The</str<strong>on</strong>g> surface roughness <strong>on</strong> RAAF aircraft samples was R max =64-125µm<br />

and R z =30-60µm as marked, indicating a possible shorter fatigue life than <strong>the</strong> laboratory<br />

c<strong>on</strong>diti<strong>on</strong>s indicated.<br />

23