The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

The Effect of Peening on the Fatigue Life of 7050 Aluminium Alloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DSTO-RR-0208<br />

50<br />

Total <strong>Fatigue</strong> <strong>Life</strong>, Programs<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 20 40 60 80 100<br />

Percentage <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>Fatigue</strong> <strong>Life</strong> Expended before <str<strong>on</strong>g>Peening</str<strong>on</strong>g>, %<br />

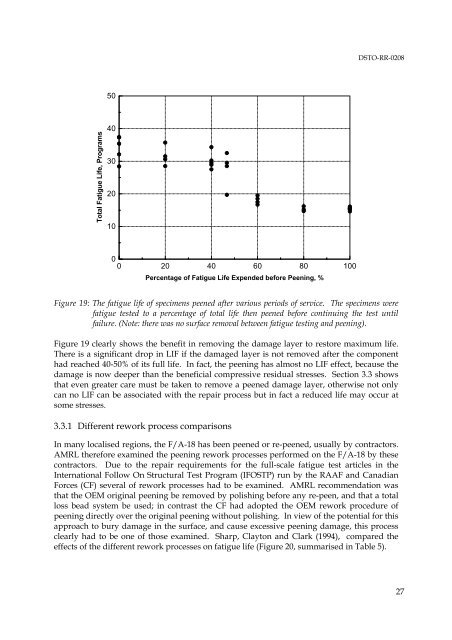

Figure 19: <str<strong>on</strong>g>The</str<strong>on</strong>g> fatigue life <str<strong>on</strong>g>of</str<strong>on</strong>g> specimens peened after various periods <str<strong>on</strong>g>of</str<strong>on</strong>g> service. <str<strong>on</strong>g>The</str<strong>on</strong>g> specimens were<br />

fatigue tested to a percentage <str<strong>on</strong>g>of</str<strong>on</strong>g> total life <strong>the</strong>n peened before c<strong>on</strong>tinuing <strong>the</strong> test until<br />

failure. (Note: <strong>the</strong>re was no surface removal between fatigue testing and peening).<br />

Figure 19 clearly shows <strong>the</strong> benefit in removing <strong>the</strong> damage layer to restore maximum life.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g>re is a significant drop in LIF if <strong>the</strong> damaged layer is not removed after <strong>the</strong> comp<strong>on</strong>ent<br />

had reached 40-50% <str<strong>on</strong>g>of</str<strong>on</strong>g> its full life. In fact, <strong>the</strong> peening has almost no LIF effect, because <strong>the</strong><br />

damage is now deeper than <strong>the</strong> beneficial compressive residual stresses. Secti<strong>on</strong> 3.3 shows<br />

that even greater care must be taken to remove a peened damage layer, o<strong>the</strong>rwise not <strong>on</strong>ly<br />

can no LIF can be associated with <strong>the</strong> repair process but in fact a reduced life may occur at<br />

some stresses.<br />

3.3.1 Different rework process comparis<strong>on</strong>s<br />

In many localised regi<strong>on</strong>s, <strong>the</strong> F/A-18 has been peened or re-peened, usually by c<strong>on</strong>tractors.<br />

AMRL <strong>the</strong>refore examined <strong>the</strong> peening rework processes performed <strong>on</strong> <strong>the</strong> F/A-18 by <strong>the</strong>se<br />

c<strong>on</strong>tractors. Due to <strong>the</strong> repair requirements for <strong>the</strong> full-scale fatigue test articles in <strong>the</strong><br />

Internati<strong>on</strong>al Follow On Structural Test Program (IFOSTP) run by <strong>the</strong> RAAF and Canadian<br />

Forces (CF) several <str<strong>on</strong>g>of</str<strong>on</strong>g> rework processes had to be examined. AMRL recommendati<strong>on</strong> was<br />

that <strong>the</strong> OEM original peening be removed by polishing before any re-peen, and that a total<br />

loss bead system be used; in c<strong>on</strong>trast <strong>the</strong> CF had adopted <strong>the</strong> OEM rework procedure <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

peening directly over <strong>the</strong> original peening without polishing. In view <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> potential for this<br />

approach to bury damage in <strong>the</strong> surface, and cause excessive peening damage, this process<br />

clearly had to be <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> those examined. Sharp, Clayt<strong>on</strong> and Clark (1994), compared <strong>the</strong><br />

effects <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> different rework processes <strong>on</strong> fatigue life (Figure 20, summarised in Table 5).<br />

27