Low Cost Torch Height Control Install and Setup Manual - CandCNC

Low Cost Torch Height Control Install and Setup Manual - CandCNC

Low Cost Torch Height Control Install and Setup Manual - CandCNC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J15<br />

Tip<br />

Volts<br />

Workclamp<br />

+ [POS]<br />

L4<br />

R7<br />

- [NEG]<br />

Electrode<br />

36 THC Sensor<br />

39<br />

REV 14<br />

L2<br />

L1<br />

J11<br />

37<br />

ARC OK<br />

J3<br />

R2<br />

Volts<br />

<strong>Torch</strong><br />

Switch J10<br />

+<br />

Arc<br />

J5<br />

D2<br />

OK<br />

J4<br />

TP4<br />

TP3<br />

TP1<br />

TP2<br />

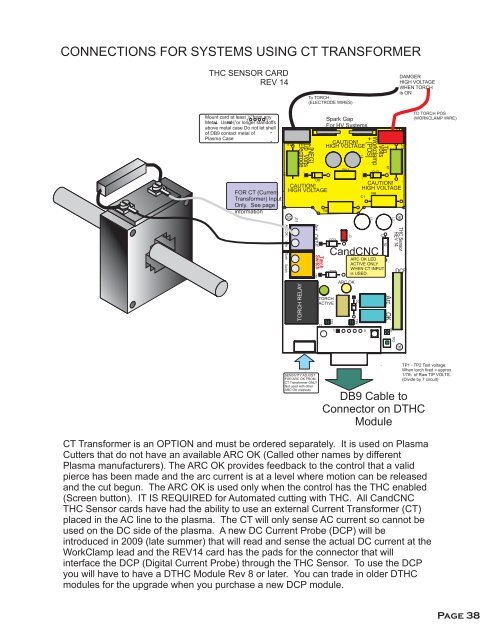

CONNECTIONS FOR SYSTEMS USING CT TRANSFORMER<br />

THC SENSOR CARD<br />

REV 14<br />

To TORCH -<br />

(ELECTRODE WIRES)<br />

DAMGER<br />

HIGH VOLTAGE<br />

WHEN TORCH<br />

is ON<br />

Mount card at least ½”from any<br />

6<br />

9<br />

Metal. UseVR2<br />

½”or longer st<strong>and</strong>offs<br />

above metal case Do not let shell<br />

of DB9 contact metal of<br />

Plasma Case<br />

FOR CT (Current<br />

Transformer) Input<br />

Only. See page<br />

information<br />

R1<br />

J14<br />

Tip Volts<br />

D6<br />

CAUTION!<br />

HIGH VOLTAGE<br />

Spark Gap<br />

For HV Systems<br />

J17<br />

CAUTION!<br />

HIGH VOLTAGE<br />

R6<br />

RV1<br />

J16<br />

D13<br />

CAUTION!<br />

HIGH VOLTAGE<br />

C1<br />

R8<br />

TO TORCH POS<br />

(WORKCLAMP WIRE)<br />

<strong>Torch</strong> Switch<br />

TORCH RELAY<br />

Arc OK[V]<br />

D22<br />

C<strong>and</strong>CNC<br />

D21<br />

TORCH<br />

ACTIVE<br />

ARC OK<br />

C2<br />

ARC OK LED<br />

ACTIVE ONLY<br />

WHEN CT INPUT<br />

is USED.<br />

DCP<br />

J1<br />

1<br />

5<br />

SENSIVITY ADJUST<br />

FOR ARC OK FROM<br />

CT Transformer ONLY<br />

Not used with other<br />

ARC OK methods<br />

TP1 - TP2 Test voltage:<br />

When torch fired = approx<br />

1/7th of Raw TIP VOLTS.<br />

(Divide by 7 circuit)<br />

DB9 Cable to<br />

Connector on DTHC<br />

Module<br />

CT Transformer is an OPTION <strong>and</strong> must be ordered separately. It is used on Plasma<br />

Cutters that do not have an available ARC OK (Called other names by different<br />

Plasma manufacturers). The ARC OK provides feedback to the control that a valid<br />

pierce has been made <strong>and</strong> the arc current is at a level where motion can be released<br />

<strong>and</strong> the cut begun. The ARC OK is used only when the control has the THC enabled<br />

(Screen button). IT IS REQUIRED for Automated cutting with THC. All C<strong>and</strong>CNC<br />

THC Sensor cards have had the ability to use an external Current Transformer (CT)<br />

placed in the AC line to the plasma. The CT will only sense AC current so cannot be<br />

used on the DC side of the plasma. A new DC Current Probe (DCP) will be<br />

introduced in 2009 (late summer) that will read <strong>and</strong> sense the actual DC current at the<br />

WorkClamp lead <strong>and</strong> the REV14 card has the pads for the connector that will<br />

interface the DCP (Digital Current Probe) through the THC Sensor. To use the DCP<br />

you will have to have a DTHC Module Rev 8 or later. You can trade in older DTHC<br />

modules for the upgrade when you purchase a new DCP module.<br />

Page 38