TCAEY-THAEY 115÷238 - Rhoss

TCAEY-THAEY 115÷238 - Rhoss

TCAEY-THAEY 115÷238 - Rhoss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TCAEY</strong>-<strong>THAEY</strong>-TXAEY 115÷238<br />

water connections<br />

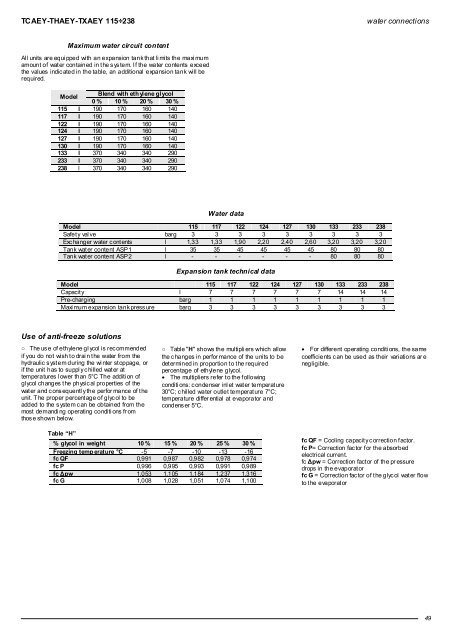

Maximum water circuit content<br />

All units are equi pped with an expansion tank that li mits the maxi mum<br />

amount of wat er contained in t he s ys tem. I f the water contents exceed<br />

the values indicated in the table, an additional expansion tank will be<br />

required.<br />

Model<br />

Blend with ethylene glycol<br />

0 % 10 % 20 % 30 %<br />

115 l 190 170 160 140<br />

117 l 190 170 160 140<br />

122 l 190 170 160 140<br />

124 l 190 170 160 140<br />

127 l 190 170 160 140<br />

130 l 190 170 160 140<br />

133 l 370 340 340 290<br />

233 l 370 340 340 290<br />

238 l 370 340 340 290<br />

Water data<br />

Model 115 117 122 124 127 130 133 233 238<br />

Safet y val ve barg 3 3 3 3 3 3 3 3 3<br />

Exc hanger water c ont ents l 1,33 1,33 1,90 2,20 2,40 2,60 3,20 3,20 3,20<br />

Tank wat er content ASP1 l 35 35 45 45 45 45 80 80 80<br />

Tank water content ASP2 l - - - - - - 80 80 80<br />

Expansion tank technical data<br />

Model 115 117 122 124 127 130 133 233 238<br />

Capacit y l 7 7 7 7 7 7 14 14 14<br />

Pre-charging barg 1 1 1 1 1 1 1 1 1<br />

Maxi mum expansion tank press ure barg 3 3 3 3 3 3 3 3 3<br />

Use of anti-freeze solutions<br />

○ The us e of ethylene gl ycol is rec ommended<br />

if you do not wish t o drai n t he water from the<br />

hydraulic s yst em during the wi nter st oppage, or<br />

if the unit has to suppl y c hilled wat er at<br />

temperatures l ower than 5°C The additi on of<br />

glycol changes t he physic al properties of the<br />

wat er and c ons equentl y the perfor mance of t he<br />

unit. T he proper percent age of glyc ol to be<br />

added to the s ystem c an be obtained from the<br />

most demandi ng operating conditi ons fr om<br />

thos e shown below.<br />

○ Table "H" shows the multipliers which allow<br />

the changes in performance of the units to be<br />

det ermined in proportion t o t he required<br />

percentage of ethylene glycol.<br />

• The multipliers refer to the following<br />

conditi ons: c ondenser inl et wat er temperat ure<br />

30°C; c hilled water outlet temperat ure 7°C;<br />

temperature differ ential at evaporator and<br />

condens er 5°C.<br />

• For different operating conditi ons, the same<br />

coefficients c an be used as their variations ar e<br />

negligible.<br />

Table “H”<br />

% glycol in weight 10 % 15 % 20 % 25 % 30 %<br />

Freezing temp erature °C -5 -7 -10 -13 -16<br />

fc QF 0,991 0,987 0,982 0,978 0,974<br />

fc P 0,996 0,995 0,993 0,991 0,989<br />

fc Δpw 1,053 1,105 1,184 1,237 1,316<br />

fc G 1,008 1,028 1,051 1,074 1,100<br />

fc QF = Cooling capacit y c orrection f actor.<br />

fc P= Correction factor for the absorbed<br />

electrical current.<br />

fc Δpw = Correction fact or of the pr essure<br />

drops in the evaporat or<br />

fc G = Correction fac tor of t he glyc ol wat er flow<br />

to t he evaporat or<br />

49