Metos Marine Galley and Laundry Equipment

Metos Marine Galley and Laundry Equipment

Metos Marine Galley and Laundry Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

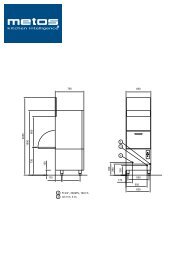

METOS ICS+ RACK CONVEYOR MACHINES<br />

Best control for the operator<br />

The New ICS+<br />

6 washing programmes<br />

Contact time is one of the main factors for successful<br />

washing result. Contact time means the time that dishes<br />

spend inside the machine starting from the fi rst pump<br />

aided pre-wash zone up to the fresh water fi nal rinse. According<br />

to the German DIN 10510 contact time in a rack<br />

conveyor machine should be 120 seconds. Even in many<br />

Contact time control panel<br />

Contact time control panel<br />

Easy adjusment of contact time<br />

This panel provides easy adjustment of contact time.<br />

In <strong>Metos</strong> 153 ICS+ machine the contact time starts from 40 seconds<br />

<strong>and</strong> can be adjusted up to 160 seconds. Lightly soiled dishes such as<br />

trays can be washed with shorter contact time. Heavily soiled goods<br />

such as food preparation utensils require a long contact time.<br />

The new <strong>Metos</strong> ICS+ machine also informs <strong>and</strong> guides the operator.<br />

The display gives information of following:<br />

Washing: Washing is on. Washing light is lid alone during power<br />

wash.<br />

Rinsing: Rinsing is on. Conveyor is moving. Washing <strong>and</strong> rinsing lights<br />

are lid simultaneously during transfer wash.<br />

Next basket: machine is in st<strong>and</strong> by position <strong>and</strong> waiting for next<br />

basket. Machine packing baskets continuously line <strong>and</strong> reducing idle of<br />

machine. Washing <strong>and</strong> rinsing are not on. Conveyor is not moving.<br />

cases a good washing result can be reached already with<br />

shorter contact time, the control over the contact time is<br />

always as important.<br />

<strong>Metos</strong> ICS+ control panels<br />

The new <strong>Metos</strong> ICS+ provides better control over contact<br />

time than any other rack conveyor machine.<br />

Operating panel<br />

Operating panel<br />

Operating instructions on the display (several languages available)<br />

The display indicates the progress of the wash. The display provides<br />

on-line user guidance. The machine gives a warning, if the water supply<br />

is interrupted, the overfl ow pipes are not in place or for any reason if<br />

the machine is not ready for use.<br />

HACCP<br />

The unit controls the temperatures of the wash tanks <strong>and</strong> the fi nal<br />

rinse <strong>and</strong> provides a low temperature warning.<br />

The washer controls the water fl ow of the fi nal rinse <strong>and</strong> generates<br />

a crystal-clear rinsing result.<br />

Diagnostics<br />

The number of washed racks <strong>and</strong> the water consumption can be<br />

read on the display.<br />

Error indications on the display. In a service situation the most important<br />

components can be tested by push buttons.<br />

| 195