Metos Marine Galley and Laundry Equipment

Metos Marine Galley and Laundry Equipment

Metos Marine Galley and Laundry Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

202 |<br />

METOS ICS+/WD PRE-RINSE ZONE<br />

Drying zone T-80<br />

Angle drying zone T-80<br />

The <strong>Metos</strong> ICS+ angle loading<br />

table makes installation in tight<br />

spaces possible.<br />

PRESSURE BOOSTER PUMP<br />

A pressure boosting pump is used when the dynamic<br />

tap water pressure is below 250 kPa.<br />

Pressure booster pump<br />

<strong>Metos</strong> ICS+/WD<br />

The pre-rinse zone saves water <strong>and</strong> work. The pre-rinse zone attached permanently to the machine recycles<br />

water within the machine. In the pre-rinse zone designed for WD 153/151E the dishes are fi rst rinsed<br />

with cold water <strong>and</strong> thereafter with the recyclable fi nal rinse water. The pre-rinse zone to be attached to<br />

the 213-423/211-421E machines recycles the pre-wash water with a pump. The double strainers that are<br />

removed from the front can be emptied without stopping the machine.<br />

Pre-rinse zone Inst. length<br />

R-L 153/151E 400 mm<br />

L-R 153/151E 400 mm<br />

R-L 213-423/211-421E 400 mm<br />

L-R 213-423/211-421E 400 mm<br />

METOS ICS+/WD DRYING ZONE<br />

The machines can be equipped with a T-60, T-80, T-90 or T-180 drying zone. The zone’s powerful fan blows<br />

hot air from above the dishes. It pays to use a drying zone when large amounts of less heat-absorbing<br />

dishes are to be washed. Plastic dishes <strong>and</strong> trays are such dishes. The air diversion sheet distributes the<br />

blown air evenly above the dishes, which cuts energy consumption. Part of the thermal energy is utilized<br />

in heat recovery, through which the cold water is fed to the machine. The thermal power is 6 kW for T-60,<br />

T-80 <strong>and</strong> T-90, 2x6 kW for T-180. Also angle dryer is available for the machines.<br />

Total kW power with drying zone<br />

Drying zone 153/151 213/211 243/241 333/331 423/421 Inst. length<br />

T-60 38,6 46,1 46,1 53,6 62,6 600 mm<br />

T-80 38,6 46,1 46,1 53,6 62,6 800 mm<br />

T-90 38,6 46,1 46,1 53,6 62,6 900 mm<br />

T-180 45,4 52,8 52,8 60,4 69,4 1800 mm<br />

90°/180° 38,6 46,1 46,1 53,6 62,6 820 mm<br />

Powered turn track 180° for angle dryer 780 mm<br />

Powered turn track 90° for angle dryer 780 mm<br />

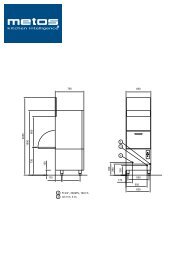

METOS ANGLE LOADING TABLE<br />

The angle loading table reduces the system’s installation length <strong>and</strong> enables installation in limited<br />

spaces. The angle loading table is attached to the rack conveyor; no extra motor is needed. The angle<br />

loading table is available for both for right- <strong>and</strong> left-feeded machines. The construction is of stainless<br />

steel throughout, the legs have plastic adjustment pads. St<strong>and</strong>ard installation length 630 mm, by special<br />

order 630 to 2000 mm.<br />

Angle loading table Inst. length<br />

<strong>Metos</strong> ICS+ 630 mm<br />

<strong>Metos</strong> WD 630 mm<br />

INSTALLATION KITS<br />

If motor-driven conveyors are attached to the machine, they have to be connected<br />

to the washing machine’s control system. The functions of the feeding conveyor<br />

can be controlled from the machine (e.g. chain rinsing). For these functions the<br />

machine is equipped with installation kits.<br />

Installation kits<br />

For entry conveyor WD-E <strong>and</strong> ICS<br />

For exit conveyor WD-E<br />

For exit conveyor ICS<br />

For entry/exit conveyors WD-E<br />

For entry/exit conveyors ICS<br />

For chain rinsing<br />

For timer for basin rinse<br />

For pre-rinse on curve<br />

For pre-rinse on a straight conveyor<br />

For external pre-rinse machine’s pressure booster pump<br />

Water connection from rack conveyor for PRM 60/90