a review - Acta Technica Corviniensis

a review - Acta Technica Corviniensis

a review - Acta Technica Corviniensis

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ACTA TECHNICA CORVINIENSIS – Bulletin of Engineering<br />

(Nwachukwu, 2005). Depending upon the type of data<br />

available, the water availability can be computed<br />

from one of the following method, namely; direct<br />

observation method and rain-fall run-off series<br />

method.<br />

STREAM FLOW DATA ANALYSIS<br />

The main objective of stream flow record analysis in<br />

SHP development is to prepare a flow duration curve<br />

and then determine design flow, installed capacity,<br />

plant capacity factor and average discharge.<br />

In order to ascertain how often flow of a given<br />

magnitude occurred during the period of record, a<br />

flow duration curve is prepared. From available data,<br />

the discharge is plotted as ordinate against the<br />

percent of time that discharge is exceeded on the<br />

abscissa and this can be of daily, mean monthly or<br />

mean annual flows.<br />

Flow duration curves from long-term monthly stream<br />

flow records offer a convenient tool in plant capacity<br />

design (Nwachukwu, 2005).<br />

The procedure used to prepare a flow-duration curve<br />

is as follows, demonstrated with a case study of Osun<br />

River.<br />

Table 1: Mean monthly stream flow (m 3 /s) of Osun River<br />

YEAR JAN FEB MAR APR MAY JUNE<br />

1979 84 89 74 97 158 127<br />

1980 74 59 49 69 159 262<br />

1981 42 58 76 111 228 176<br />

1982 65 69 93 82 150 266<br />

1983 73 132 62 116 154 144<br />

1984 33 64 42 97 140 129<br />

1985 105 97 42 67 114 132<br />

YEAR JULY AUG SEP OCT NOV DEC<br />

1979 89 56 48 47 72 136<br />

1980 108 69 47 110 114 81<br />

1981 118 66 47 46 65 65<br />

1982 187 82 55 42 96 76<br />

1983 129 68 42 84 145 155<br />

1984 104 62 43 56 55 51<br />

1985 144 75 50 35 23 24<br />

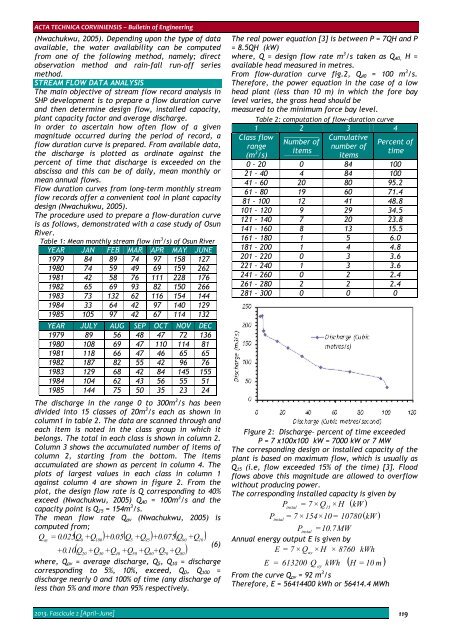

The discharge in the range 0 to 300m 3 /s has been<br />

divided into 15 classes of 20m 3 /s each as shown in<br />

column1 in table 2. The data are scanned through and<br />

each item is noted in the class group in which it<br />

belongs. The total in each class is shown in column 2.<br />

Column 3 shows the accumulated number of items of<br />

column 2, starting from the bottom. The items<br />

accumulated are shown as percent in column 4. The<br />

plots of largest values in each class in column 1<br />

against column 4 are shown in figure 2. From the<br />

plot, the design flow rate is Q corresponding to 40%<br />

exceed (Nwachukwu, 2005) Q 40 = 100m 3 /s and the<br />

capacity point is Q 15 = 154m 3 /s.<br />

The mean flow rate Q av (Nwachukwu, 2005) is<br />

computed from;<br />

Q ( ) ( ) ( )<br />

ay<br />

= 0.025Q0<br />

+ Q100<br />

+ 0.05 Q5<br />

+ Q95<br />

+ 0.075 Q90<br />

+ Q10<br />

(6)<br />

+ 0.10Q ( )<br />

20<br />

+ Q30<br />

+ Q40<br />

+ Q50<br />

+ Q60+<br />

Q70<br />

+ Q80<br />

where, Q av = average discharge, Q 5 , Q 10 = discharge<br />

corresponding to 5%, 10%, exceed, Q 0 , Q 100 =<br />

discharge nearly 0 and 100% of time (any discharge of<br />

less than 5% and more than 95% respectively.<br />

The real power equation [3] is between P = 7QH and P<br />

= 8.5QH (kW)<br />

where, Q = design flow rate m 3 /s taken as Q 40, H =<br />

available head measured in metres.<br />

From flow-duration curve fig.2, Q 40 = 100 m 3 /s.<br />

Therefore, the power equation in the case of a low<br />

head plant (less than 10 m) in which the fore bay<br />

level varies, the gross head should be<br />

measured to the minimum force bay level.<br />

Table 2: computation of flow-duration curve<br />

1 2 3 4<br />

Class flow<br />

range<br />

(m 3 /s)<br />

Number of<br />

items<br />

Cumulative<br />

number of<br />

items<br />

Percent of<br />

time<br />

0 – 20 0 84 100<br />

21 – 40 4 84 100<br />

41 – 60 20 80 95.2<br />

61 – 80 19 60 71.4<br />

81 – 100 12 41 48.8<br />

101 – 120 9 29 34.5<br />

121 – 140 7 20 23.8<br />

141 – 160 8 13 15.5<br />

161 – 180 1 5 6.0<br />

181 – 200 1 4 4.8<br />

201 – 220 0 3 3.6<br />

221 – 240 1 3 3.6<br />

241 – 260 0 2 2.4<br />

261 – 280 2 2 2.4<br />

281 – 300 0 0 0<br />

Figure 2: Discharge– percent of time exceeded<br />

P = 7 x100x100 kW = 7000 kW or 7 MW<br />

The corresponding design or installed capacity of the<br />

plant is based on maximum flow, which is usually as<br />

Q 15 (i.e, flow exceeded 15% of the time) [3]. Flood<br />

flows above this magnitude are allowed to overflow<br />

without producing power.<br />

The corresponding installed capacity is given by<br />

Pinstal = 7 × Q15<br />

× H<br />

P instal<br />

= 7 × 154×<br />

10 =<br />

P instal<br />

= 10.7MW<br />

Annual energy output E is given by<br />

E = 7 × Qay × H × 8760<br />

( kW )<br />

10780 ( kW )<br />

kWh<br />

( )<br />

E = 613200 Q<br />

ay<br />

kWh H = 10 m<br />

From the curve Q av = 92 m 3 /s<br />

Therefore, E = 56414400 kWh or 56414.4 MWh<br />

2013. Fascicule 2 [April–June] 119