ENGINE SHOP REBUILD & SERVICE PARTS MANUAL - Jacobsen

ENGINE SHOP REBUILD & SERVICE PARTS MANUAL - Jacobsen

ENGINE SHOP REBUILD & SERVICE PARTS MANUAL - Jacobsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

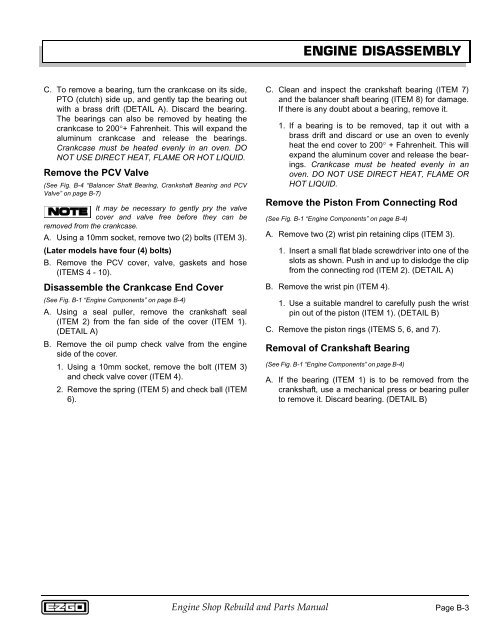

<strong>ENGINE</strong> DISASSEMBLY<br />

C. To remove a bearing, turn the crankcase on its side,<br />

PTO (clutch) side up, and gently tap the bearing out<br />

with a brass drift (DETAIL A). Discard the bearing.<br />

The bearings can also be removed by heating the<br />

crankcase to 200°+ Fahrenheit. This will expand the<br />

aluminum crankcase and release the bearings.<br />

Crankcase must be heated evenly in an oven. DO<br />

NOT USE DIRECT HEAT, FLAME OR HOT LIQUID.<br />

Remove the PCV Valve<br />

(See Fig. B-4 “Balancer Shaft Bearing, Crankshaft Bearing and PCV<br />

Valve” on page B-7)<br />

It may be necessary to gently pry the valve<br />

cover and valve free before they can be<br />

removed from the crankcase.<br />

A. Using a 10mm socket, remove two (2) bolts (ITEM 3).<br />

(Later models have four (4) bolts)<br />

B. Remove the PCV cover, valve, gaskets and hose<br />

(ITEMS 4 - 10).<br />

Disassemble the Crankcase End Cover<br />

(See Fig. B-1 “Engine Components” on page B-4)<br />

A. Using a seal puller, remove the crankshaft seal<br />

(ITEM 2) from the fan side of the cover (ITEM 1).<br />

(DETAIL A)<br />

B. Remove the oil pump check valve from the engine<br />

side of the cover.<br />

1. Using a 10mm socket, remove the bolt (ITEM 3)<br />

and check valve cover (ITEM 4).<br />

2. Remove the spring (ITEM 5) and check ball (ITEM<br />

6).<br />

C. Clean and inspect the crankshaft bearing (ITEM 7)<br />

and the balancer shaft bearing (ITEM 8) for damage.<br />

If there is any doubt about a bearing, remove it.<br />

1. If a bearing is to be removed, tap it out with a<br />

brass drift and discard or use an oven to evenly<br />

heat the end cover to 200° + Fahrenheit. This will<br />

expand the aluminum cover and release the bearings.<br />

Crankcase must be heated evenly in an<br />

oven. DO NOT USE DIRECT HEAT, FLAME OR<br />

HOT LIQUID.<br />

Remove the Piston From Connecting Rod<br />

(See Fig. B-1 “Engine Components” on page B-4)<br />

A. Remove two (2) wrist pin retaining clips (ITEM 3).<br />

1. Insert a small flat blade screwdriver into one of the<br />

slots as shown. Push in and up to dislodge the clip<br />

from the connecting rod (ITEM 2). (DETAIL A)<br />

B. Remove the wrist pin (ITEM 4).<br />

1. Use a suitable mandrel to carefully push the wrist<br />

pin out of the piston (ITEM 1). (DETAIL B)<br />

C. Remove the piston rings (ITEMS 5, 6, and 7).<br />

Removal of Crankshaft Bearing<br />

(See Fig. B-1 “Engine Components” on page B-4)<br />

A. If the bearing (ITEM 1) is to be removed from the<br />

crankshaft, use a mechanical press or bearing puller<br />

to remove it. Discard bearing. (DETAIL B)<br />

Engine Shop Rebuild and Parts Manual<br />

Page B-3