Annual Report - 2005-06 - GAIL (India)

Annual Report - 2005-06 - GAIL (India)

Annual Report - 2005-06 - GAIL (India)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

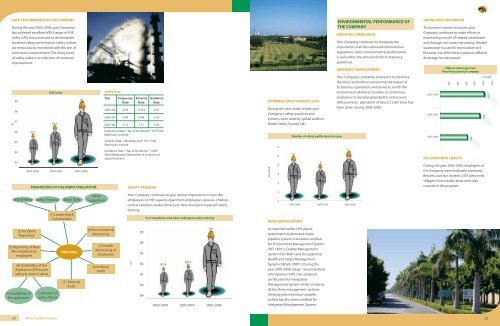

SAFE PERFORMANCE OF THE COMPANY<br />

During the year <strong>2005</strong>-20<strong>06</strong>, your Company<br />

has achieved excellent MOU target of HSE<br />

index. <strong>GAIL</strong> has continued to demonstrate<br />

excellent safety performance. Safety Indices<br />

are meticulously monitored with the aim of<br />

continuous improvement. The rising trend<br />

of safety index is an indicator of continual<br />

improvement.<br />

%<br />

99<br />

98<br />

97<br />

96<br />

95<br />

94<br />

93<br />

95.2<br />

HSE Index<br />

96.4<br />

2003-2004 2004-<strong>2005</strong> <strong>2005</strong>-20<strong>06</strong><br />

PARAMETERS OF HSE INDEX EVALUATION<br />

HSE Briefing Safety Training Mock Drills<br />

(1) Leadership &<br />

Commitment<br />

99<br />

Safety<br />

Suggestions<br />

Safety Data<br />

Year Frequency Severity Incidence<br />

Rate Rate Rate<br />

2003-04 0.18 15.43 0.47<br />

2004-05 0.09 6.69 0.25<br />

<strong>2005</strong>-<strong>06</strong> 0.13 7.11 0.35<br />

Frequency Rate = No. of Accidents * 10 6 /Total<br />

Manhours worked<br />

Severity Rate = Mandays lost* 10 6 / Total<br />

Manhours worked<br />

Incidence Rate = No. of Accidents * 1000/<br />

Total Manpower (Manpower is inclusive of<br />

causal workers)<br />

SAFETY TRAINING<br />

Your Company continues to give utmost importance to train the<br />

employees on HSE aspects. Apart from employees, spouses, children,<br />

contract workers, tanker drivers etc. have also been imparted safety<br />

training.<br />

% of employees who have undergone safety training<br />

EXTERNAL SAFETY AUDITS (ESA)<br />

During the year under review, your<br />

Company’s safety practices and<br />

systems were rated by global auditors-<br />

British Safety Council-UK.<br />

No. of ESA<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

NEW CERTIFICATIONS<br />

Number of safety audits done in a year<br />

10<br />

8<br />

2003-2004 2004-<strong>2005</strong> <strong>2005</strong>-20<strong>06</strong><br />

ENVIRONMENTAL PERFORMANCE OF<br />

THE COMPANY<br />

ENSURING COMPLIANCE<br />

Your Company continues to recognize the<br />

importance of all the national & international<br />

regulations. <strong>GAIL</strong>’s environmental performance<br />

is well within the emission limits in statutory<br />

guidelines.<br />

GREENBELT DEVELOPMENT<br />

Your Company constantly endeavors to minimize<br />

the direct and indirect environmental impact of<br />

its business operations and strives to enrich the<br />

environment wherever possible. In continuous<br />

endeavour to develop greenbelt in and around<br />

<strong>GAIL</strong> premises, plantation of about 2 Lakh trees has<br />

been done during <strong>2005</strong>-20<strong>06</strong>.<br />

11<br />

SAVING PRECIOUS WATER<br />

To conserve natural resources, your<br />

Company continues to make efforts in<br />

maximizing recycle of treated wastewater<br />

and through rain water harvesting. Treated<br />

wastewater is used for horticulture and<br />

firewater use. With these measures effluent<br />

discharge has decreased.<br />

2003-2004<br />

2004-<strong>2005</strong><br />

<strong>2005</strong>-20<strong>06</strong><br />

Effluent discharge from<br />

Pata Petrochemical complex<br />

200<br />

400<br />

OCCUPATIONAL HEALTH<br />

600<br />

640<br />

800<br />

1000<br />

During the year <strong>2005</strong>-20<strong>06</strong>, employees of<br />

the Company were medically examined.<br />

Besides, contract workers, CISF personnel,<br />

villagers from nearby areas were also<br />

covered in the program.<br />

(1,000M 3 )<br />

930<br />

1010<br />

1200<br />

(2) Incidents<br />

<strong>Report</strong>ing<br />

(3) <strong>Report</strong>ing of Near<br />

Miss Incidents by<br />

employees<br />

(4) Availability of Fire<br />

Appliances & Pressure<br />

safety & control valves<br />

% Availability of<br />

fire appliances<br />

Caibration of<br />

safety Valves<br />

HSE Index<br />

(5 ) External<br />

Audit<br />

(8) Environmental<br />

Monitoring<br />

(7) Health<br />

Monitoring of<br />

employees<br />

(6) Internal<br />

Audit<br />

(%)<br />

95<br />

94<br />

93<br />

92<br />

91<br />

90<br />

89<br />

95<br />

91.4<br />

92.3<br />

2003-2004 2004-<strong>2005</strong> <strong>2005</strong>-20<strong>06</strong><br />

As reported earlier LPG plants,<br />

petrochemical plant and major<br />

pipeline systems have been certified<br />

for Environment Management System<br />

(ISO 14001), Quality Management<br />

System (ISO 9001) and Occupational<br />

Health and Safety Management<br />

System (OHSAS 18001). During the<br />

year <strong>2005</strong>-20<strong>06</strong>, Vizag – Secunderabad<br />

LPG Pipeline (VSPL) has obtained<br />

certification for Integrated<br />

Management System which combines<br />

all the three management systems.<br />

Similarly petrochemical complex<br />

at Pata has also been certified for<br />

Integrated Management System.<br />

24 Winning Momentum 25