Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fadhel - Recent Advancements in <strong>Solar</strong> <strong>Drying</strong><br />

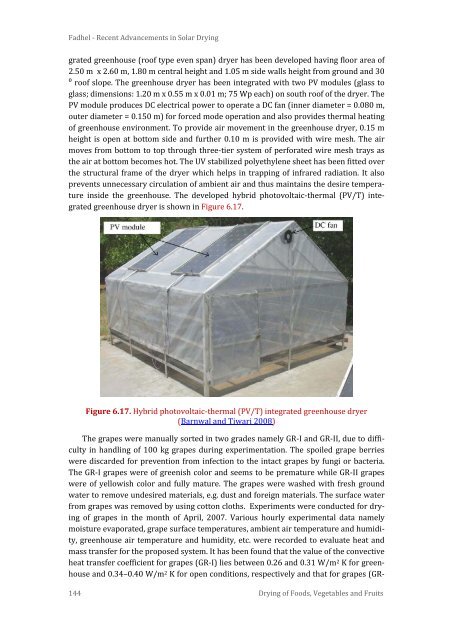

grated greenhouse (roof type even span) dryer has been developed having floor area of<br />

2.50 m x 2.60 m, 1.80 m central height <strong>and</strong> 1.05 m side walls height from ground <strong>and</strong> 30<br />

⁰ roof slope. The greenhouse dryer has been integrated with two PV modules (glass to<br />

glass; dimensions: 1.20 m x 0.55 m x 0.01 m; 75 Wp each) on south roof of the dryer. The<br />

PV module produces DC electrical power to operate a DC fan (inner diameter = 0.080 m,<br />

outer diameter = 0.150 m) for forced mode operation <strong>and</strong> also provides thermal heating<br />

of greenhouse environment. To provide air movement in the greenhouse dryer, 0.15 m<br />

height is open at bottom side <strong>and</strong> further 0.10 m is provided with wire mesh. The air<br />

moves from bottom to top through three-tier system of perforated wire mesh trays as<br />

the air at bottom becomes hot. The UV stabilized polyethylene sheet has been fitted over<br />

the structural frame of the dryer which helps in trapping of infrared radiation. It also<br />

prevents unnecessary circulation of ambient air <strong>and</strong> thus maintains the desire temperature<br />

inside the greenhouse. The developed hybrid photovoltaic-thermal (PV/T) integrated<br />

greenhouse dryer is shown in Figure 6.17.<br />

Figure 6.17. Hybrid photovoltaic-thermal (PV/T) integrated greenhouse dryer<br />

(Barnwal <strong>and</strong> Tiwari 2008)<br />

The grapes were manually sorted in two grades namely GR-I <strong>and</strong> GR-II, due to difficulty<br />

in h<strong>and</strong>ling of 100 kg grapes during experimentation. The spoiled grape berries<br />

were discarded for prevention from infection to the intact grapes by fungi or bacteria.<br />

The GR-I grapes were of greenish color <strong>and</strong> seems to be premature while GR-II grapes<br />

were of yellowish color <strong>and</strong> fully mature. The grapes were washed with fresh ground<br />

water to remove undesired materials, e.g. dust <strong>and</strong> foreign materials. The surface water<br />

from grapes was removed by using cotton cloths. Experiments were conducted for drying<br />

of grapes in the month of April, 2007. Various hourly experimental data namely<br />

moisture evaporated, grape surface temperatures, ambient air temperature <strong>and</strong> humidity,<br />

greenhouse air temperature <strong>and</strong> humidity, etc. were recorded to evaluate heat <strong>and</strong><br />

mass transfer for the proposed system. It has been found that the value of the convective<br />

heat transfer coefficient for grapes (GR-I) lies between 0.26 <strong>and</strong> 0.31 W/m 2 K for greenhouse<br />

<strong>and</strong> 0.34–0.40 W/m 2 K for open conditions, respectively <strong>and</strong> that for grapes (GR-<br />

144 <strong>Drying</strong> of Foods, Vegetables <strong>and</strong> Fruits