Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hii <strong>and</strong> Law - <strong>Solar</strong> <strong>Drying</strong> of Major Commodity Products<br />

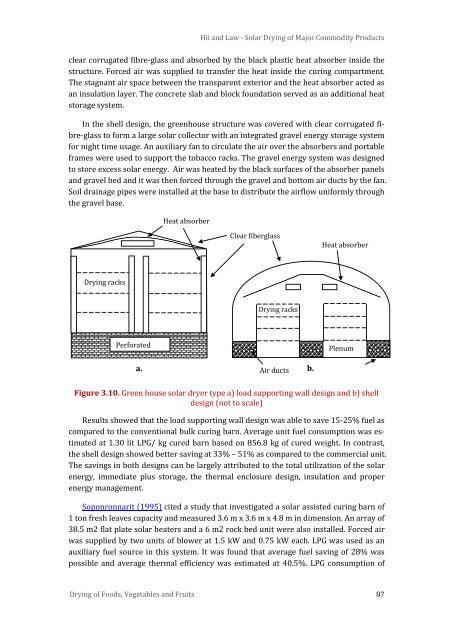

clear corrugated fibre-glass <strong>and</strong> absorbed by the black plastic heat absorber inside the<br />

structure. Forced air was supplied to transfer the heat inside the curing compartment.<br />

The stagnant air space between the transparent exterior <strong>and</strong> the heat absorber acted as<br />

an insulation layer. The concrete slab <strong>and</strong> block foundation served as an additional heat<br />

storage system.<br />

In the shell design, the greenhouse structure was covered with clear corrugated fibre-glass<br />

to form a large solar collector with an integrated gravel energy storage system<br />

for night time usage. An auxiliary fan to circulate the air over the absorbers <strong>and</strong> portable<br />

frames were used to support the tobacco racks. The gravel energy system was designed<br />

to store excess solar energy. Air was heated by the black surfaces of the absorber panels<br />

<strong>and</strong> gravel bed <strong>and</strong> it was then forced through the gravel <strong>and</strong> bottom air ducts by the fan.<br />

Soil drainage pipes were installed at the base to distribute the airflow uniformly through<br />

the gravel base.<br />

Heat absorber<br />

Clear fiberglass<br />

Heat absorber<br />

<strong>Drying</strong> racks<br />

<strong>Drying</strong> racks<br />

<strong>Drying</strong> racks<br />

Perforated<br />

Plenum<br />

a. Air ducts b.<br />

Figure 3.10. Green house solar dryer type a) load supporting wall design <strong>and</strong> b) shell<br />

design (not to scale)<br />

Results showed that the load supporting wall design was able to save 15-25% fuel as<br />

compared to the conventional bulk curing barn. Average unit fuel consumption was estimated<br />

at 1.30 lit LPG/ kg cured barn based on 856.8 kg of cured weight. In contrast,<br />

the shell design showed better saving at 33% – 51% as compared to the commercial unit.<br />

The savings in both designs can be largely attributed to the total utilization of the solar<br />

energy, immediate plus storage, the thermal enclosure design, insulation <strong>and</strong> proper<br />

energy management.<br />

Soponronnarit (1995) cited a study that investigated a solar assisted curing barn of<br />

1 ton fresh leaves capacity <strong>and</strong> measured 3.6 m x 3.6 m x 4.8 m in dimension. An array of<br />

38.5 m2 flat plate solar heaters <strong>and</strong> a 6 m2 rock bed unit were also installed. Forced air<br />

was supplied by two units of blower at 1.5 kW <strong>and</strong> 0.75 kW each. LPG was used as an<br />

auxiliary fuel source in this system. It was found that average fuel saving of 28% was<br />

possible <strong>and</strong> average thermal efficiency was estimated at 40.5%. LPG consumption of<br />

<strong>Drying</strong> of Foods, Vegetables <strong>and</strong> Fruits 87