Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

Solar Drying: Fundamentals,Applications and Innovations - National ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hii <strong>and</strong> Law - <strong>Solar</strong> <strong>Drying</strong> of Major Commodity Products<br />

solar collector had a V-corrugated absorption plat of two air passes <strong>and</strong> covered with<br />

single glass. Total collector area measured 2.04 m 2 . The dimension of the drying chamber<br />

measured 1.06 m x 0.66 m x 0.56 m <strong>and</strong> can be loaded with 38 kg of corn. Moisture<br />

content reduction from 21% to 13% can be achieved in 4 hours. The range of drying air<br />

temperature obtained was from 30°C to 45°C at ambient condition of 8.5°C to 20°C. The<br />

solar collector efficiency can be raised by 3.25% <strong>and</strong> 11.11% by increasing the volumetric<br />

air flow rate from 0.025 m 3 /s to 0.03 m 3 /s <strong>and</strong> 0.03 m 3 /s to 0.035 m 3 /s, respectively.<br />

3.2.3. Cocoa<br />

The solar dryers developed for cocoa drying falls under various categories of design<br />

i.e. direct, indirect, tunnel <strong>and</strong> green house effect solar drying systems. Minka (1986)<br />

re-ported no increase in drying rates as compared to sun drying. The solar dryers tested<br />

were the marquee dryer, which consisted of a drying platform covered by transparent<br />

structure <strong>and</strong> the solar cabinet dryer. Bonarparte et al. (1998) developed <strong>and</strong> tested direct<br />

solar cabinet (13.5 kg/m 2 loading) <strong>and</strong> indirect solar dryers (40.4 kg/m 2 loading)<br />

<strong>and</strong> observed temperature increment up to 20°C <strong>and</strong> 15°C above ambient recorded in<br />

these dryers, respectively. Hii et al. (2006) reported no significant finding in product<br />

quality between solar <strong>and</strong> sun dried cocoa beans as quality changes occurred in a rather<br />

similar rate in both drying systems (20 kg per batch drying load). The solar dryer developed<br />

measured 153 cm x 91.5 cm in area with perforation measured at 1 cm diameter<br />

holes arranged in 2 cm square pitch.<br />

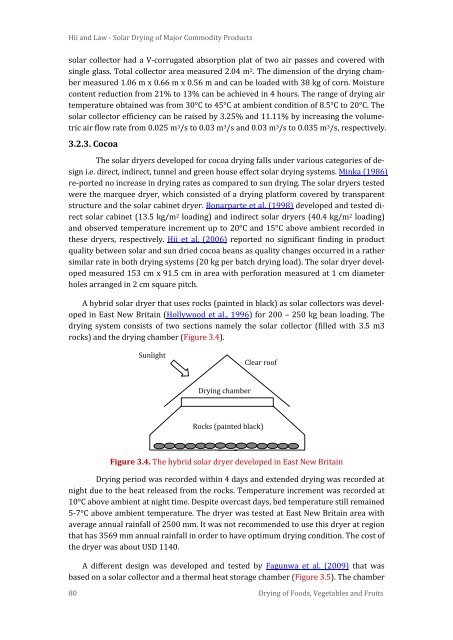

A hybrid solar dryer that uses rocks (painted in black) as solar collectors was developed<br />

in East New Britain (Hollywood et al., 1996) for 200 – 250 kg bean loading. The<br />

drying system consists of two sections namely the solar collector (filled with 3.5 m3<br />

rocks) <strong>and</strong> the drying chamber (Figure 3.4).<br />

Sunlight<br />

Clear roof<br />

<strong>Drying</strong> chamber<br />

Rocks (painted black)<br />

Figure 3.4. The hybrid solar dryer developed in East New Britain<br />

<strong>Drying</strong> period was recorded within 4 days <strong>and</strong> extended drying was recorded at<br />

night due to the heat released from the rocks. Temperature increment was recorded at<br />

10°C above ambient at night time. Despite overcast days, bed temperature still remained<br />

5-7°C above ambient temperature. The dryer was tested at East New Britain area with<br />

average annual rainfall of 2500 mm. It was not recommended to use this dryer at region<br />

that has 3569 mm annual rainfall in order to have optimum drying condition. The cost of<br />

the dryer was about USD 1140.<br />

A different design was developed <strong>and</strong> tested by Fagunwa et al. (2009) that was<br />

based on a solar collector <strong>and</strong> a thermal heat storage chamber (Figure 3.5). The chamber<br />

80 <strong>Drying</strong> of Foods, Vegetables <strong>and</strong> Fruits