OPERATING AND MAINTENANCE INSTRUCTIONS MINICOLOR

OPERATING AND MAINTENANCE INSTRUCTIONS MINICOLOR

OPERATING AND MAINTENANCE INSTRUCTIONS MINICOLOR

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Operation<br />

<strong>MINICOLOR</strong><br />

5 Operation<br />

Operation with the COLOR A control unit see separate manual.<br />

5.1 Operation with the <strong>MINICOLOR</strong> S1 control unit (one dosing station, without timer)<br />

5.1.1 Calibration - with extruders<br />

Calibration is effected by two calibration measurements.<br />

A. First calibration<br />

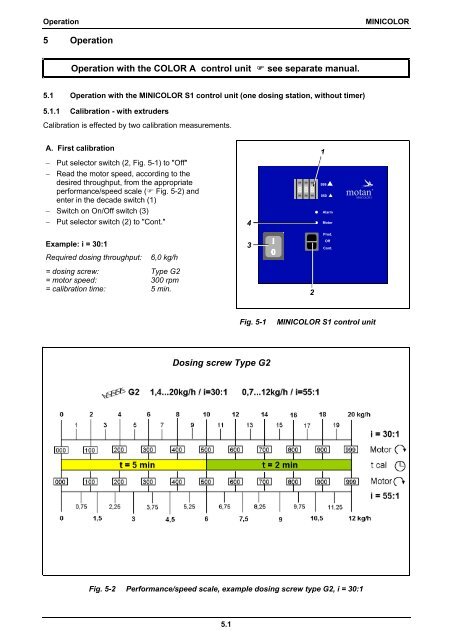

− Put selector switch (2, Fig. 5-1) to "Off"<br />

− Read the motor speed, according to the<br />

desired throughput, from the appropriate<br />

performance/speed scale ( Fig. 5-2) and<br />

enter in the decade switch (1)<br />

− Switch on On/Off switch (3)<br />

− Put selector switch (2) to "Cont."<br />

4<br />

1<br />

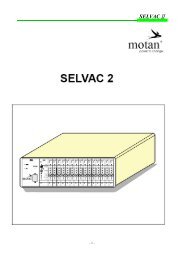

Example: i = 30:1<br />

Required dosing throughput:<br />

6,0 kg/h<br />

= dosing screw: Type G2<br />

= motor speed: 300 rpm<br />

= calibration time: 5 min.<br />

3<br />

2<br />

Fig. 5-1<br />

<strong>MINICOLOR</strong> S1 control unit<br />

Dosing screw Type G2<br />

Fig. 5-2 Performance/speed scale, example dosing screw type G2, i = 30:1<br />

5.1