DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Roller Chains for Power Transmission Designing of Chain Transmission<br />

Roller Chains for<br />

Power Transmission<br />

1. The description in this chapter can be applied when a<br />

<strong>chain</strong> is endlessly engaged<br />

for transmission with two<br />

sprockets parallel in their<br />

shafts and accurate in<br />

alignment as illustrated<br />

below.<br />

Drive<br />

Driven<br />

Top<br />

End<br />

2. Consult us when a <strong>chain</strong> is to be used for lifting, pulling<br />

dollies or being engaged with a pin gear, etc.<br />

3. When there are any regulations or guidelines concerning<br />

the selection of <strong>chain</strong>s, select a <strong>chain</strong> in accordance<br />

with such regulations and the maximum kilowatt ratings<br />

(Drive performance) table described below, and choose<br />

the one with a larger allowance.<br />

Designing of Chain<br />

Transmission<br />

How to Select the Proper Chain<br />

The <strong>chain</strong> can be selected according to the following two<br />

methods:<br />

(1) Selection by drive performance<br />

(2) Low-speed selection<br />

The drive performance method considers not only <strong>chain</strong><br />

tension but also the shock load on the bushings and <strong>roller</strong>s<br />

due to the engagement between the sprockets and the<br />

<strong>chain</strong>, and the wear of pins, bushings and <strong>roller</strong>s.<br />

The slow-speed method is applied when the <strong>chain</strong> is<br />

operated at a speed of 50 rpm or less. In general, the <strong>chain</strong><br />

selected by this method is subject to conditions more<br />

severe than that selected according to the selection by<br />

drive performance. Thus, carefully assess the conditions<br />

when selecting with this method.<br />

Selection by drive performance<br />

First, the following information is required.<br />

qPower to be transmitted (kW)<br />

wSpeeds of driving shaft and driven shaft (speed ratio)<br />

and shaft diameters<br />

eCenter distance between driving shaft and driven shaft<br />

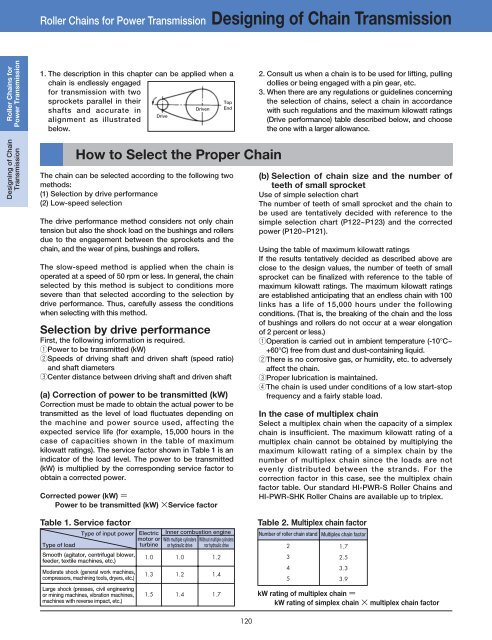

(a) Correction of power to be transmitted (kW)<br />

Correction must be made to obtain the actual power to be<br />

transmitted as the level of load fluctuates depending on<br />

the machine and power source used, affecting the<br />

expected service life (for example, 15,000 hours in the<br />

case of capacities shown in the table of maximum<br />

kilowatt ratings). The service factor shown in Table 1 is an<br />

indicator of the load level. The power to be transmitted<br />

(kW) is multiplied by the corresponding service factor to<br />

obtain a corrected power.<br />

Corrected power (kW) <br />

Power to be transmitted (kW) Service factor<br />

(b) Selection of <strong>chain</strong> size and the number of<br />

teeth of small sprocket<br />

Use of simple selection chart<br />

The number of teeth of small sprocket and the <strong>chain</strong> to<br />

be used are tentatively decided with reference to the<br />

simple selection chart (P122~P123) and the corrected<br />

power (P120~P121).<br />

Using the table of maximum kilowatt ratings<br />

If the results tentatively decided as described above are<br />

close to the design values, the number of teeth of small<br />

sprocket can be finalized with reference to the table of<br />

maximum kilowatt ratings. The maximum kilowatt ratings<br />

are established anticipating that an endless <strong>chain</strong> with 100<br />

links has a life of 15,000 hours under the following<br />

conditions. (That is, the breaking of the <strong>chain</strong> and the loss<br />

of bushings and <strong>roller</strong>s do not occur at a wear elongation<br />

of 2 percent or less.)<br />

qOperation is carried out in ambient temperature (-10°C~<br />

+<strong>60</strong>°C) free from dust and dust-containing liquid.<br />

wThere is no corrosive gas, or humidity, etc. to adversely<br />

affect the <strong>chain</strong>.<br />

eProper lubrication is maintained.<br />

rThe <strong>chain</strong> is used under conditions of a low start-stop<br />

frequency and a fairly stable load.<br />

In the case of multiplex <strong>chain</strong><br />

Select a multiplex <strong>chain</strong> when the capacity of a simplex<br />

<strong>chain</strong> is insufficient. The maximum kilowatt rating of a<br />

multiplex <strong>chain</strong> cannot be obtained by multiplying the<br />

maximum kilowatt rating of a simplex <strong>chain</strong> by the<br />

number of multiplex <strong>chain</strong> since the loads are not<br />

evenly distributed between the strands. For the<br />

correction factor in this case, see the multiplex <strong>chain</strong><br />

factor table. Our <strong>standard</strong> HI-PWR-S Roller Chains and<br />

HI-PWR-SHK Roller Chains are available up to triplex.<br />

Table 1. Service factor<br />

Type of input power Electric Inner combustion engine<br />

motor or With multiple cylinders Without multiple cylinders<br />

Type of load<br />

turbine or hydraulic drive nor hydraulic drive<br />

Smooth (agitator, centrifugal blower,<br />

1.0 1.0 1.2<br />

feeder, textile machines, etc.)<br />

Moderate shock (general work machines,<br />

compressors, machining tools, dryers, etc.)<br />

Large shock (presses, civil engineering<br />

or mining machines, vibration machines,<br />

machines with reverse impact, etc.)<br />

1.3<br />

1.5<br />

1.2<br />

1.4<br />

1.4<br />

1.7<br />

Table 2. Multiplex <strong>chain</strong> factor<br />

Number of <strong>roller</strong> <strong>chain</strong> stand<br />

2<br />

3<br />

4<br />

5<br />

Multiplex <strong>chain</strong> factor<br />

1.7<br />

2.5<br />

3.3<br />

3.9<br />

kW rating of multiplex <strong>chain</strong> <br />

kW rating of simplex <strong>chain</strong> multiplex <strong>chain</strong> factor<br />

120