DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

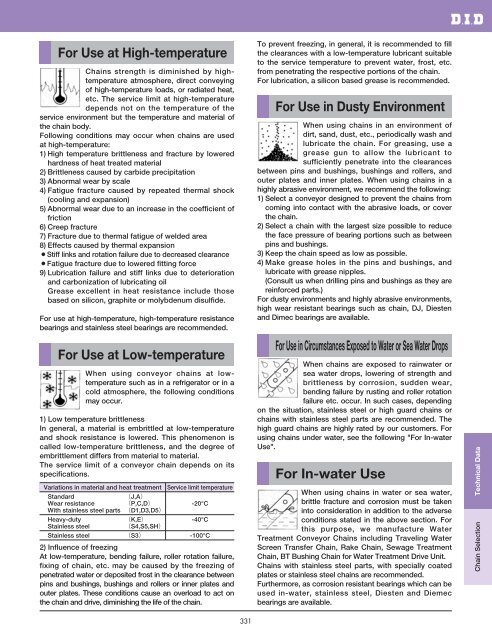

For Use at High-temperature<br />

Chains strength is diminished by hightemperature<br />

atmosphere, direct conveying<br />

of high-temperature loads, or radiated heat,<br />

etc. The service limit at high-temperature<br />

depends not on the temperature of the<br />

service environment but the temperature and material of<br />

the <strong>chain</strong> body.<br />

Following conditions may occur when <strong>chain</strong>s are used<br />

at high-temperature:<br />

1) High temperature brittleness and fracture by lowered<br />

hardness of heat treated material<br />

2) Brittleness caused by carbide precipitation<br />

3) Abnormal wear by scale<br />

4) Fatigue fracture caused by repeated thermal shock<br />

(cooling and expansion)<br />

5) Abnormal wear due to an increase in the coefficient of<br />

friction<br />

6) Creep fracture<br />

7) Fracture due to thermal fatigue of welded area<br />

8) Effects caused by thermal expansion<br />

¡Stiff links and rotation failure due to decreased clearance<br />

¡Fatigue fracture due to lowered fitting force<br />

9) Lubrication failure and stiff links due to deterioration<br />

and carbonization of lubricating oil<br />

Grease excellent in heat resistance include those<br />

based on silicon, graphite or molybdenum disulfide.<br />

For use at high-temperature, high-temperature resistance<br />

bearings and stainless steel bearings are recommended.<br />

For Use at Low-temperature<br />

When using conveyor <strong>chain</strong>s at lowtemperature<br />

such as in a refrigerator or in a<br />

cold atmosphere, the following conditions<br />

may occur.<br />

1) Low temperature brittleness<br />

In general, a material is embrittled at low-temperature<br />

and shock resistance is lowered. This phenomenon is<br />

called low-temperature brittleness, and the degree of<br />

embrittlement differs from material to material.<br />

The service limit of a conveyor <strong>chain</strong> depends on its<br />

specifications.<br />

Variations in material and heat treatment Service limit temperature<br />

Standard<br />

J,A<br />

Wear resistance P,C,D -20°C<br />

With stainless steel parts D1,D3,D5<br />

Heavy-duty K,E -40°C<br />

Stainless steel<br />

S4,S5,SH<br />

Stainless steel S3 -100°C<br />

2) Influence of freezing<br />

At low-temperature, bending failure, <strong>roller</strong> rotation failure,<br />

fixing of <strong>chain</strong>, etc. may be caused by the freezing of<br />

penetrated water or deposited frost in the clearance between<br />

pins and bushings, bushings and <strong>roller</strong>s or inner plates and<br />

outer plates. These conditions cause an overload to act on<br />

the <strong>chain</strong> and drive, diminishing the life of the <strong>chain</strong>.<br />

To prevent freezing, in general, it is recommended to fill<br />

the clearances with a low-temperature lubricant suitable<br />

to the service temperature to prevent water, frost, etc.<br />

from penetrating the respective portions of the <strong>chain</strong>.<br />

For lubrication, a silicon based grease is recommended.<br />

For Use in Dusty Environment<br />

When using <strong>chain</strong>s in an environment of<br />

dirt, sand, dust, etc., periodically wash and<br />

lubricate the <strong>chain</strong>. For greasing, use a<br />

grease gun to allow the lubricant to<br />

sufficiently penetrate into the clearances<br />

between pins and bushings, bushings and <strong>roller</strong>s, and<br />

outer plates and inner plates. When using <strong>chain</strong>s in a<br />

highly abrasive environment, we recommend the following:<br />

1) Select a conveyor designed to prevent the <strong>chain</strong>s from<br />

coming into contact with the abrasive loads, or cover<br />

the <strong>chain</strong>.<br />

2) Select a <strong>chain</strong> with the largest size possible to reduce<br />

the face pressure of bearing portions such as between<br />

pins and bushings.<br />

3) Keep the <strong>chain</strong> speed as low as possible.<br />

4) Make grease holes in the pins and bushings, and<br />

lubricate with grease nipples.<br />

(Consult us when drilling pins and bushings as they are<br />

reinforced parts.)<br />

For dusty environments and highly abrasive environments,<br />

high wear resistant bearings such as <strong>chain</strong>, DJ, Diesten<br />

and Dimec bearings are available.<br />

For Use in Circumstances Exposed to Water or Sea Water Drops<br />

When <strong>chain</strong>s are exposed to rainwater or<br />

sea water drops, lowering of strength and<br />

brittleness by corrosion, sudden wear,<br />

bending failure by rusting and <strong>roller</strong> rotation<br />

failure etc. occur. In such cases, depending<br />

on the situation, stainless steel or high guard <strong>chain</strong>s or<br />

<strong>chain</strong>s with stainless steel parts are recommended. The<br />

high guard <strong>chain</strong>s are highly rated by our customers. For<br />

using <strong>chain</strong>s under water, see the following "For In-water<br />

Use".<br />

For In-water Use<br />

When using <strong>chain</strong>s in water or sea water,<br />

brittle fracture and corrosion must be taken<br />

into consideration in addition to the adverse<br />

conditions stated in the above section. For<br />

this purpose, we manufacture Water<br />

Treatment Conveyor Chains including Traveling Water<br />

Screen Transfer Chain, Rake Chain, Sewage Treatment<br />

Chain, BT Bushing Chain for Water Treatment Drive Unit.<br />

Chains with stainless steel parts, with specially coated<br />

plates or stainless steel <strong>chain</strong>s are recommended.<br />

Furthermore, as corrosion resistant bearings which can be<br />

used in-water, stainless steel, Diesten and Diemec<br />

bearings are available.<br />

Technical Data<br />

Chain Selection<br />

331