DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

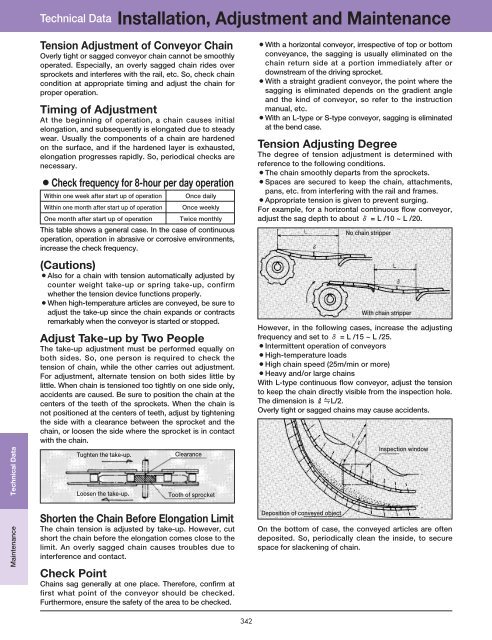

Technical Data Installation, Adjustment and Maintenance<br />

Technical Data<br />

Tension Adjustment of Conveyor Chain<br />

Overly tight or sagged conveyor <strong>chain</strong> cannot be smoothly<br />

operated. Especially, an overly sagged <strong>chain</strong> rides over<br />

sprockets and interferes with the rail, etc. So, check <strong>chain</strong><br />

condition at appropriate timing and adjust the <strong>chain</strong> for<br />

proper operation.<br />

Timing of Adjustment<br />

At the beginning of operation, a <strong>chain</strong> causes initial<br />

elongation, and subsequently is elongated due to steady<br />

wear. Usually the components of a <strong>chain</strong> are hardened<br />

on the surface, and if the hardened layer is exhausted,<br />

elongation progresses rapidly. So, periodical checks are<br />

necessary.<br />

¡Check frequency for 8-hour per day operation<br />

Within one week after start up of operation<br />

Within one month after start up of operation<br />

One month after start up of operation Twice monthly<br />

This table shows a general case. In the case of continuous<br />

operation, operation in abrasive or corrosive environments,<br />

increase the check frequency.<br />

(Cautions)<br />

¡Also for a <strong>chain</strong> with tension automatically adjusted by<br />

counter weight take-up or spring take-up, confirm<br />

whether the tension device functions properly.<br />

¡When high-temperature articles are conveyed, be sure to<br />

adjust the take-up since the <strong>chain</strong> expands or contracts<br />

remarkably when the conveyor is started or stopped.<br />

Adjust Take-up by Two People<br />

The take-up adjustment must be performed equally on<br />

both sides. So, one person is required to check the<br />

tension of <strong>chain</strong>, while the other carries out adjustment.<br />

For adjustment, alternate tension on both sides little by<br />

little. When <strong>chain</strong> is tensioned too tightly on one side only,<br />

accidents are caused. Be sure to position the <strong>chain</strong> at the<br />

centers of the teeth of the sprockets. When the <strong>chain</strong> is<br />

not positioned at the centers of teeth, adjust by tightening<br />

the side with a clearance between the sprocket and the<br />

<strong>chain</strong>, or loosen the side where the sprocket is in contact<br />

with the <strong>chain</strong>.<br />

Tughten the take-up.<br />

Loosen the take-up.<br />

Once daily<br />

Once weekly<br />

Clearance<br />

Tooth of sprocket<br />

¡With a horizontal conveyor, irrespective of top or bottom<br />

conveyance, the sagging is usually eliminated on the<br />

<strong>chain</strong> return side at a portion immediately after or<br />

downstream of the driving sprocket.<br />

¡With a straight gradient conveyor, the point where the<br />

sagging is eliminated depends on the gradient angle<br />

and the kind of conveyor, so refer to the instruction<br />

manual, etc.<br />

¡With an L-type or S-type conveyor, sagging is eliminated<br />

at the bend case.<br />

Tension Adjusting Degree<br />

The degree of tension adjustment is determined with<br />

reference to the following conditions.<br />

¡The <strong>chain</strong> smoothly departs from the sprockets.<br />

¡Spaces are secured to keep the <strong>chain</strong>, attachments,<br />

pans, etc. from interfering with the rail and frames.<br />

¡Appropriate tension is given to prevent surging.<br />

For example, for a horizontal continuous flow conveyor,<br />

adjust the sag depth to about = L /10 ~ L /20.<br />

No <strong>chain</strong> stripper<br />

With <strong>chain</strong> stripper<br />

However, in the following cases, increase the adjusting<br />

frequency and set to = L /15 ~ L /25.<br />

¡Intermittent operation of conveyors<br />

¡High-temperature loads<br />

¡High <strong>chain</strong> speed (25m/min or more)<br />

¡Heavy and/or large <strong>chain</strong>s<br />

With L-type continuous flow conveyor, adjust the tension<br />

to keep the <strong>chain</strong> directly visible from the inspection hole.<br />

The dimension is RL/2.<br />

Overly tight or sagged <strong>chain</strong>s may cause accidents.<br />

Inspection window<br />

Maintenance<br />

Shorten the Chain Before Elongation Limit<br />

The <strong>chain</strong> tension is adjusted by take-up. However, cut<br />

short the <strong>chain</strong> before the elongation comes close to the<br />

limit. An overly sagged <strong>chain</strong> causes troubles due to<br />

interference and contact.<br />

Check Point<br />

Chains sag generally at one place. Therefore, confirm at<br />

first what point of the conveyor should be checked.<br />

Furthermore, ensure the safety of the area to be checked.<br />

Deposition of conveyed object<br />

On the bottom of case, the conveyed articles are often<br />

deposited. So, periodically clean the inside, to secure<br />

space for slackening of <strong>chain</strong>.<br />

342