DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

DID 60 standard roller chain - Big Bike Webshop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

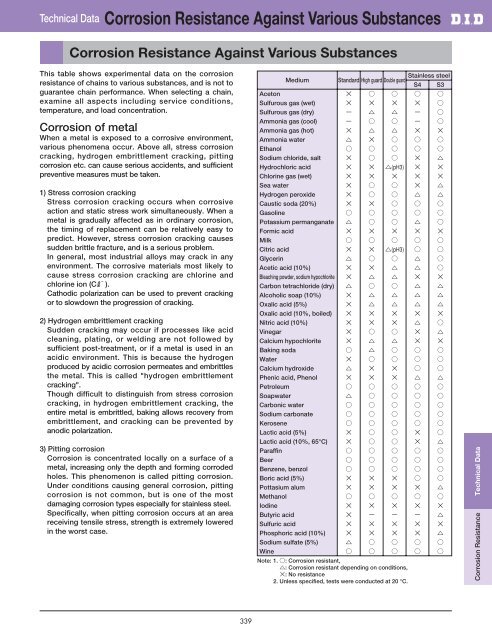

Technical Data Corrosion Resistance Against Various Substances<br />

Corrosion Resistance Against Various Substances<br />

This table shows experimental data on the corrosion<br />

resistance of <strong>chain</strong>s to various substances, and is not to<br />

guarantee <strong>chain</strong> performance. When selecting a <strong>chain</strong>,<br />

examine all aspects including service conditions,<br />

temperature, and load concentration.<br />

Corrosion of metal<br />

When a metal is exposed to a corrosive environment,<br />

various phenomena occur. Above all, stress corrosion<br />

cracking, hydrogen embrittlement cracking, pitting<br />

corrosion etc. can cause serious accidents, and sufficient<br />

preventive measures must be taken.<br />

1) Stress corrosion cracking<br />

Stress corrosion cracking occurs when corrosive<br />

action and static stress work simultaneously. When a<br />

metal is gradually affected as in ordinary corrosion,<br />

the timing of replacement can be relatively easy to<br />

predict. However, stress corrosion cracking causes<br />

sudden brittle fracture, and is a serious problem.<br />

In general, most industrial alloys may crack in any<br />

environment. The corrosive materials most likely to<br />

cause stress corrosion cracking are chlorine and<br />

chlorine ion (CR – ).<br />

Cathodic polarization can be used to prevent cracking<br />

or to slowdown the progression of cracking.<br />

2) Hydrogen embrittlement cracking<br />

Sudden cracking may occur if processes like acid<br />

cleaning, plating, or welding are not followed by<br />

sufficient post-treatment, or if a metal is used in an<br />

acidic environment. This is because the hydrogen<br />

produced by acidic corrosion permeates and embrittles<br />

the metal. This is called "hydrogen embrittlement<br />

cracking".<br />

Though difficult to distinguish from stress corrosion<br />

cracking, in hydrogen embrittlement cracking, the<br />

entire metal is embrittled, baking allows recovery from<br />

embrittlement, and cracking can be prevented by<br />

anodic polarization.<br />

3) Pitting corrosion<br />

Corrosion is concentrated locally on a surface of a<br />

metal, increasing only the depth and forming corroded<br />

holes. This phenomenon is called pitting corrosion.<br />

Under conditions causing general corrosion, pitting<br />

corrosion is not common, but is one of the most<br />

damaging corrosion types especially for stainless steel.<br />

Specifically, when pitting corrosion occurs at an area<br />

receiving tensile stress, strength is extremely lowered<br />

in the worst case.<br />

Medium<br />

Aceton<br />

Sulfurous gas (wet)<br />

Sulfurous gas (dry)<br />

Ammonia gas (cool)<br />

Ammonia gas (hot)<br />

Ammonia water<br />

Ethanol<br />

Sodium chloride, salt<br />

Hydrochloric acid<br />

Chlorine gas (wet)<br />

Sea water<br />

Hydrogen peroxide<br />

Caustic soda (20%)<br />

Gasoline<br />

Potassium permanganate<br />

Formic acid<br />

Milk<br />

Citric acid<br />

Glycerin<br />

Acetic acid (10%)<br />

Bleaching powder, sodium hypochlorite<br />

Carbon tetrachloride (dry)<br />

Alcoholic soap (10%)<br />

Oxalic acid (5%)<br />

Oxalic acid (10%, boiled)<br />

Nitric acid (10%)<br />

Vinegar<br />

Calcium hypochlorite<br />

Baking soda<br />

Water<br />

Calcium hydroxide<br />

Phenic acid, Phenol<br />

Petroleum<br />

Soapwater<br />

Carbonic water<br />

Sodium carbonate<br />

Kerosene<br />

Lactic acid (5%)<br />

Lactic acid (10%, 65°C)<br />

Paraffin<br />

Beer<br />

Benzene, benzol<br />

Boric acid (5%)<br />

Pottasium alum<br />

Methanol<br />

Iodine<br />

Butyric acid<br />

Sulfuric acid<br />

Phosphoric acid (10%)<br />

Sodium sulfate (5%)<br />

Wine<br />

Stainless steel<br />

Standard High guard Double guard<br />

S3<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Note: 1. : Corrosion resistant,<br />

: Corrosion resistant depending on conditions,<br />

: No resistance<br />

2. Unless specified, tests were conducted at 20 °C.<br />

S4<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Technical Data<br />

Corrosion Resistance<br />

339