Note 1 - Beerenberg

Note 1 - Beerenberg

Note 1 - Beerenberg

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Management report<br />

The business in 2012<br />

<strong>Beerenberg</strong>’s core operations are primarily aimed at the<br />

maintenance and modifications market. Framework conditions<br />

for the industry are undergoing significant change. The<br />

demand for innovation, increased maintenance efficiency<br />

and standardised operating models has increased as a result<br />

of an ageing platform fleet and increased demand for cost<br />

efficiency, safety and installation integrity.<br />

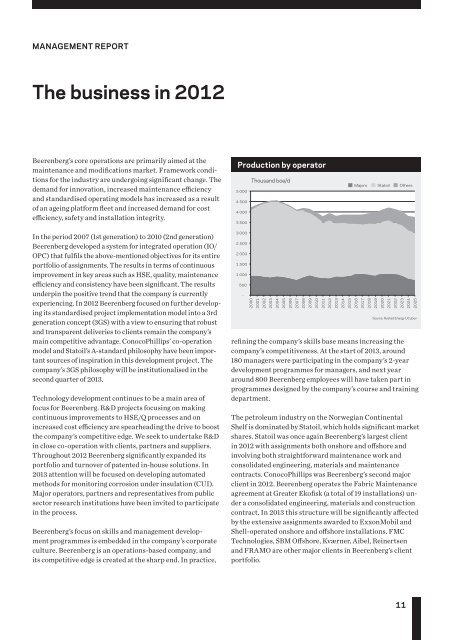

Production by operator<br />

Production by 5 000<br />

4 500<br />

4 000<br />

3 500<br />

Thousand boe/d<br />

Majors Statoil Others<br />

In the period 2007 (1st generation) to 2010 (2nd generation)<br />

<strong>Beerenberg</strong> developed a system for integrated operation (IO/<br />

OPC) that fulfils the above-mentioned objectives for its entire<br />

portfolio of assignments. The results in terms of continuous<br />

improvement in key areas such as HSE, quality, maintenance<br />

efficiency and consistency have been significant. The results<br />

underpin the positive trend that the company is currently<br />

experiencing. In 2012 <strong>Beerenberg</strong> focused on further developing<br />

its standardised project implementation model into a 3rd<br />

generation concept (3GS) with a view to ensuring that robust<br />

and transparent deliveries to clients remain the company’s<br />

main competitive advantage. ConocoPhillips’ co-operation<br />

model and Statoil’s A-standard philosophy have been important<br />

sources of inspiration in this development project. The<br />

company’s 3GS philosophy will be institutionalised in the<br />

second quarter of 2013.<br />

Technology development continues to be a main area of<br />

focus for <strong>Beerenberg</strong>. R&D projects focusing on making<br />

continuous improvements to HSE/Q processes and on<br />

increased cost efficiency are spearheading the drive to boost<br />

the company’s competitive edge. We seek to undertake R&D<br />

in close co-operation with clients, partners and suppliers.<br />

Throughout 2012 <strong>Beerenberg</strong> significantly expanded its<br />

portfolio and turnover of patented in-house solutions. In<br />

2013 attention will be focused on developing automated<br />

methods for monitoring corrosion under insulation (CUI).<br />

Major operators, partners and representatives from public<br />

sector research institutions have been invited to participate<br />

in the process.<br />

<strong>Beerenberg</strong>’s focus on skills and management development<br />

programmes is embedded in the company’s corporate<br />

culture. <strong>Beerenberg</strong> is an operations-based company, and<br />

its competitive edge is created at the sharp end. In practice,<br />

3 000<br />

2 500<br />

2 000<br />

1 500<br />

1 000<br />

500<br />

-<br />

2000<br />

2001<br />

2002<br />

2003<br />

2004<br />

2005<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

2011<br />

2012<br />

2013<br />

2014<br />

2015<br />

2016<br />

2017<br />

2018<br />

2019<br />

2020<br />

2021<br />

2022<br />

2023<br />

2024<br />

2025<br />

Source: Rystad Energy UCubev<br />

refining the company’s skills base means increasing the<br />

company’s competitiveness. At the start of 2013, around<br />

180 managers were participating in the company’s 2-year<br />

development programmes for managers, and next year<br />

around 800 <strong>Beerenberg</strong> employees will have taken part in<br />

programmes designed by the company’s course and training<br />

department.<br />

The petroleum industry on the Norwegian Continental<br />

Shelf is dominated by Statoil, which holds significant market<br />

shares. Statoil was once again <strong>Beerenberg</strong>’s largest client<br />

in 2012 with assignments both onshore and offshore and<br />

involving both straightforward maintenance work and<br />

consolidated engineering, materials and maintenance<br />

contracts. ConocoPhillips was <strong>Beerenberg</strong>’s second major<br />

client in 2012. <strong>Beerenberg</strong> operates the Fabric Maintenance<br />

agreement at Greater Ekofisk (a total of 19 installations) under<br />

a consolidated engineering, materials and construction<br />

contract. In 2013 this structure will be significantly affected<br />

by the extensive assignments awarded to ExxonMobil and<br />

Shell-operated onshore and offshore installations. FMC<br />

Technologies, SBM Offshore, Kværner, Aibel, Reinertsen<br />

and FRAMO are other major clients in <strong>Beerenberg</strong>’s client<br />

portfolio.<br />

11