3DView manual milling - Emco Maier GmbH

3DView manual milling - Emco Maier GmbH

3DView manual milling - Emco Maier GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

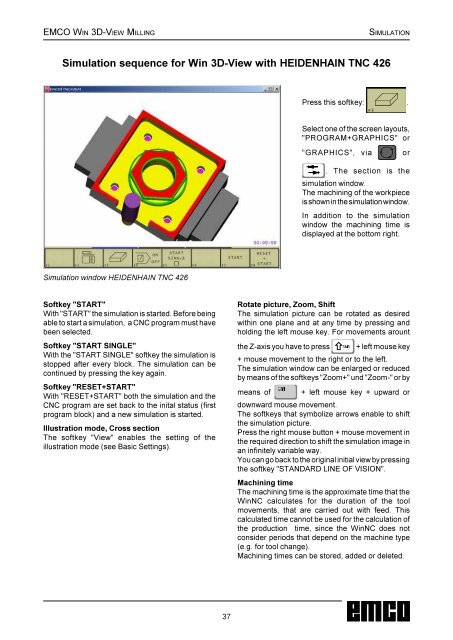

EMCO WIN 3D-VIEW MILLINGSIMULATIONSimulation sequence for Win 3D-View with HEIDENHAIN TNC 426Press this softkey: .Select one of the screen layouts,"PROGRAM+GRAPHICS" or"GRAPHICS", viaor. The section is thesimulation window.The machining of the workpieceis shown in the simulation window.In addition to the simulationwindow the machining time isdisplayed at the bottom right.Simulation window HEIDENHAIN TNC 426Softkey "START"With "START" the simulation is started. Before beingable to start a simulation, a CNC program must havebeen selected.Softkey "START SINGLE"With the "START SINGLE" softkey the simulation isstopped after every block. The simulation can becontinued by pressing the key again.Softkey "RESET+START"With "RESET+START" both the simulation and theCNC program are set back to the inital status (firstprogram block) and a new simulation is started.Illustration mode, Cross sectionThe softkey "View" enables the setting of theillustration mode (see Basic Settings).Rotate picture, Zoom, ShiftThe simulation picture can be rotated as desiredwithin one plane and at any time by pressing andholding the left mouse key. For movements arountthe Z-axis you have to press6KLIW+ left mouse key+ mouse movement to the right or to the left.The simulation window can be enlarged or reducedby means of the softkeys "Zoom+" und "Zoom-" or by&WUOmeans of + left mouse key + upward ordownward mouse movement.The softkeys that symbolize arrows enable to shiftthe simulation picture.Press the right mouse button + mouse movement inthe required direction to shift the simulation image inan infinitely variable way.You can go back to the original initial view by pressingthe softkey "STANDARD LINE OF VISION".Machining timeThe machining time is the approximate time that theWinNC calculates for the duration of the toolmovements, that are carried out with feed. Thiscalculated time cannot be used for the calculation ofthe production time, since the WinNC does notconsider periods that depend on the machine type(e.g. for tool change).Machining times can be stored, added or deleted.37