Operator's Manual

Operator's Manual

Operator's Manual

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

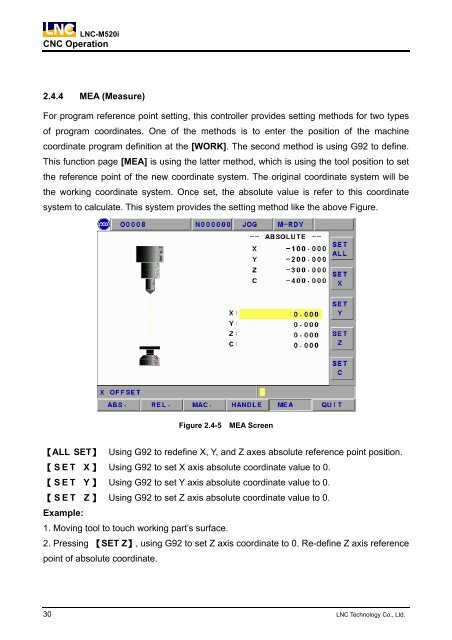

LNC-M520iCNC Operation2.4.4 MEA (Measure)For program reference point setting, this controller provides setting methods for two typesof program coordinates. One of the methods is to enter the position of the machinecoordinate program definition at the [WORK]. The second method is using G92 to define.This function page [MEA] is using the latter method, which is using the tool position to setthe reference point of the new coordinate system. The original coordinate system will bethe working coordinate system. Once set, the absolute value is refer to this coordinatesystem to calculate. This system provides the setting method like the above Figure.Figure 2.4-5 MEA Screen【ALL SET】 Using G92 to redefine X, Y, and Z axes absolute reference point position.【 SET X】 Using G92 to set X axis absolute coordinate value to 0.【 SET Y】 Using G92 to set Y axis absolute coordinate value to 0.【 SET Z】 Using G92 to set Z axis absolute coordinate value to 0.Example:1. Moving tool to touch working part’s surface.2. Pressing 【SET Z】, using G92 to set Z axis coordinate to 0. Re-define Z axis referencepoint of absolute coordinate.30 LNC Technology Co., Ltd.